Stuart Smith elected National Academy of Inventors Fellow

Prestigious distinction recognizes researcher’s impact on advanced manufacturing

January 26, 2025

Elevating UNC Charlotte’s standing in advanced research, Professor of Mechanical Engineering Stuart Smith has been elected a Fellow of the National Academy of Inventors, a status nationally recognized as the highest professional distinction awarded to inventors. This honor places Smith among an esteemed group of pioneers recognized for creating outstanding inventions that make a tangible impact on quality of life, economic development and the welfare of society.

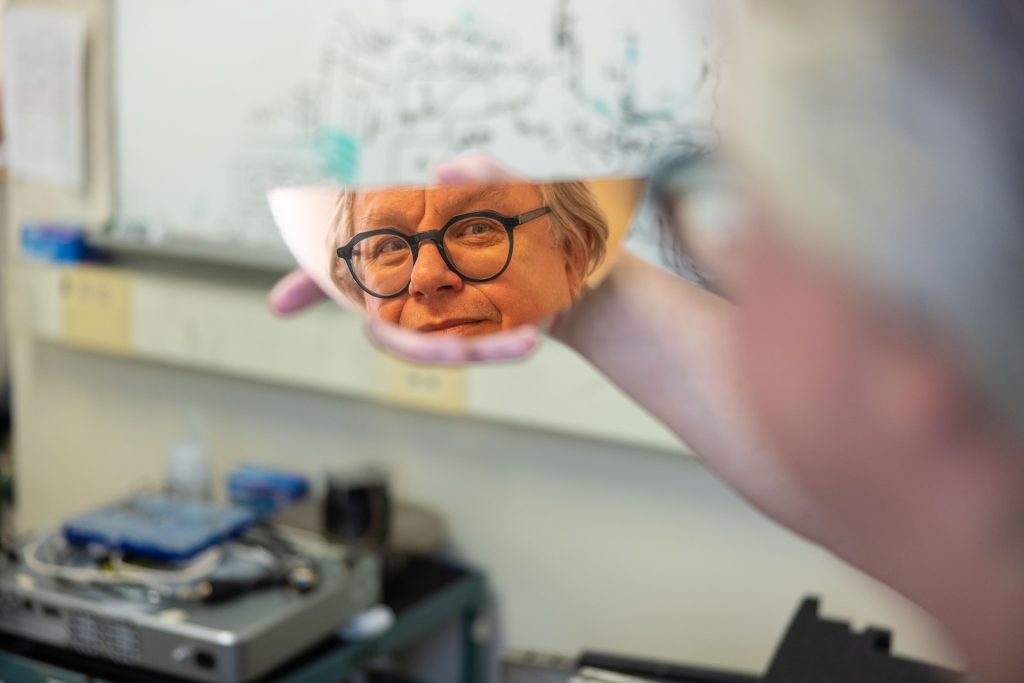

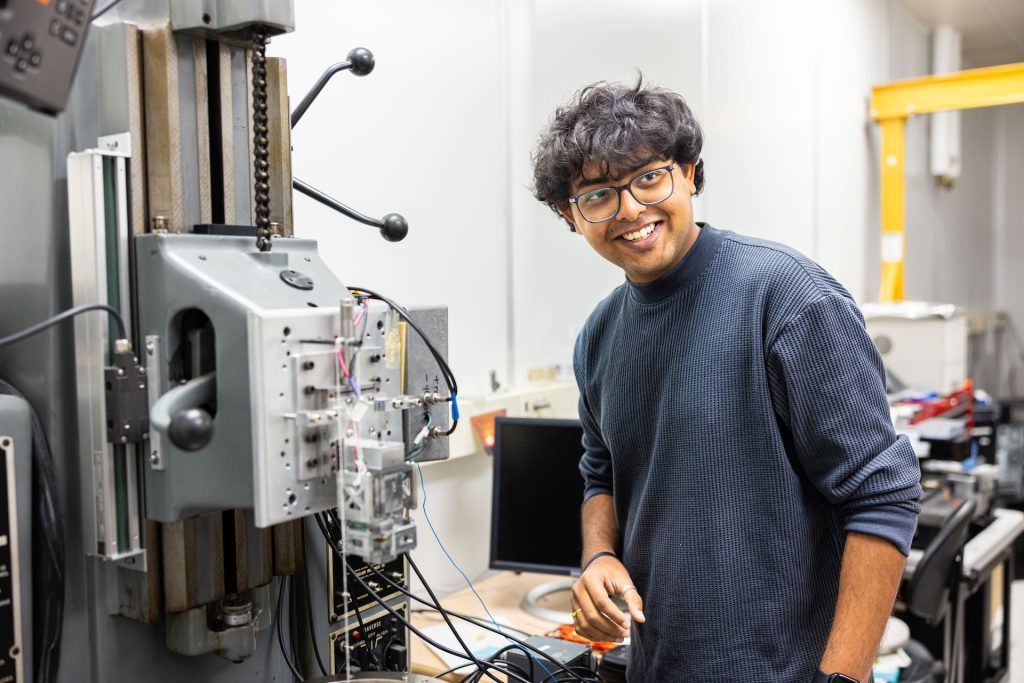

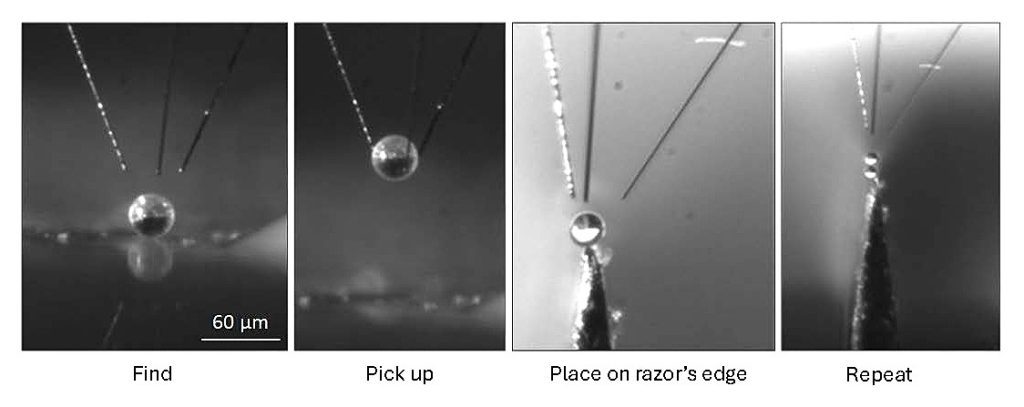

Formally, Smith researches technologies for the creation of new scientific tools and instruments that advance industrial processes. His work focuses on micro-scaled robotic systems, creating ways for manufacturers to manipulate tiny tool and part components during assembly. His research team, the Instrument Development Group, is housed within the Center for Precision Metrology in the William States Lee College of Engineering.

However, in the reality of day-to-day work, Smith is in the business of pushing technologies beyond their limits. His schedule, lab and mind are wall to wall with ongoing research, with four research projects currently all in motion simultaneously. Even with the multiple investigations, Smith maintains a brilliant focus on each, explaining, “there’s a lot of importance in every detail.”

With more than 15 patents across the U.S. and Europe, several commercialized inventions (with the outgrowth of three high-tech companies from his laboratories), five decades of published papers and multiple awards including the NAI Fellowship, Smith is a research leader in the advanced manufacturing instrumentation sector.

Fellow

15+ Patents

Over $2 Million in Research Funding

One recent research project evolved after Smith noticed the unnecessarily large amount of funds and time that engineers spend designing and implementing complex precision systems. Since multiple revisions are often necessary to perfect the designs, engineers routinely experience seemingly endless downtime and expense disassembling and rebuilding apparatuses. Even once the machinery is deployed, maintenance can be a drain to the company, especially if disassembly is required.

For example, advanced manufacturing equipment can be extremely complex, some with a large number of optical lenses that are arranged in specific positions and highly complicated interdependence. Lens position is critical to machine accuracy and the final process outcome. If they are ever taken apart, it is nearly impossible to put back together with the same accuracy.

“If the machine isn’t working correctly, it is no longer making the company money,” explained Jack Doughty, mechanical engineering master’s student and research assistant in Smith’s lab. “The business is now actively spending money to fix it. We want to reduce downtime and ensure accuracy. Sometimes, if you can’t get the equipment back up and running quickly, it may as well have been scrapped because they could’ve gotten a new machine for the cost of the downtime.”

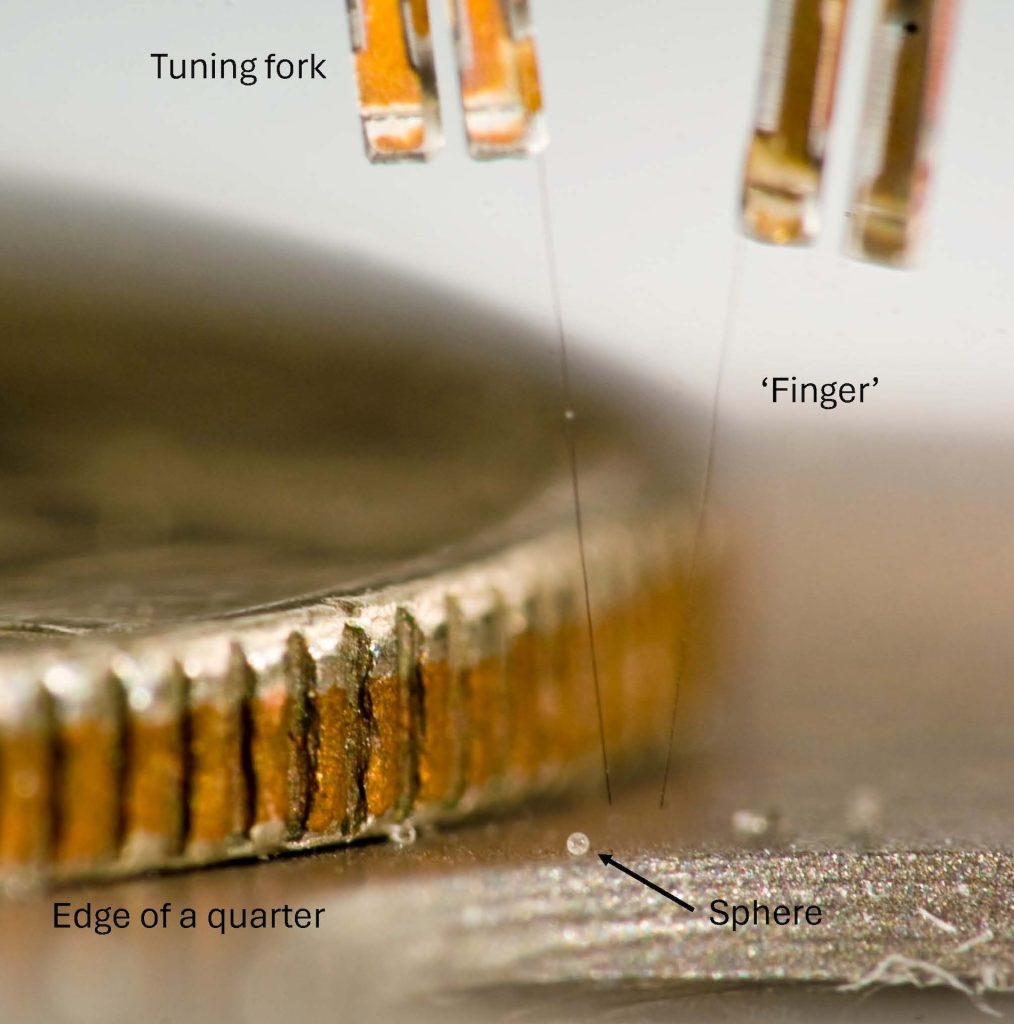

Driven by a vision of a better solution, Smith invented a toolkit that would enable engineers to streamline the design and deployment processes of mechanical systems, giving manufacturers an option to the downtime dilemma. “To save the user that time and expense,” said Smith, “we create tools that can help reassemble a machine back with the same specifications – sometimes relocating the position of components to within a countable number of atoms.”

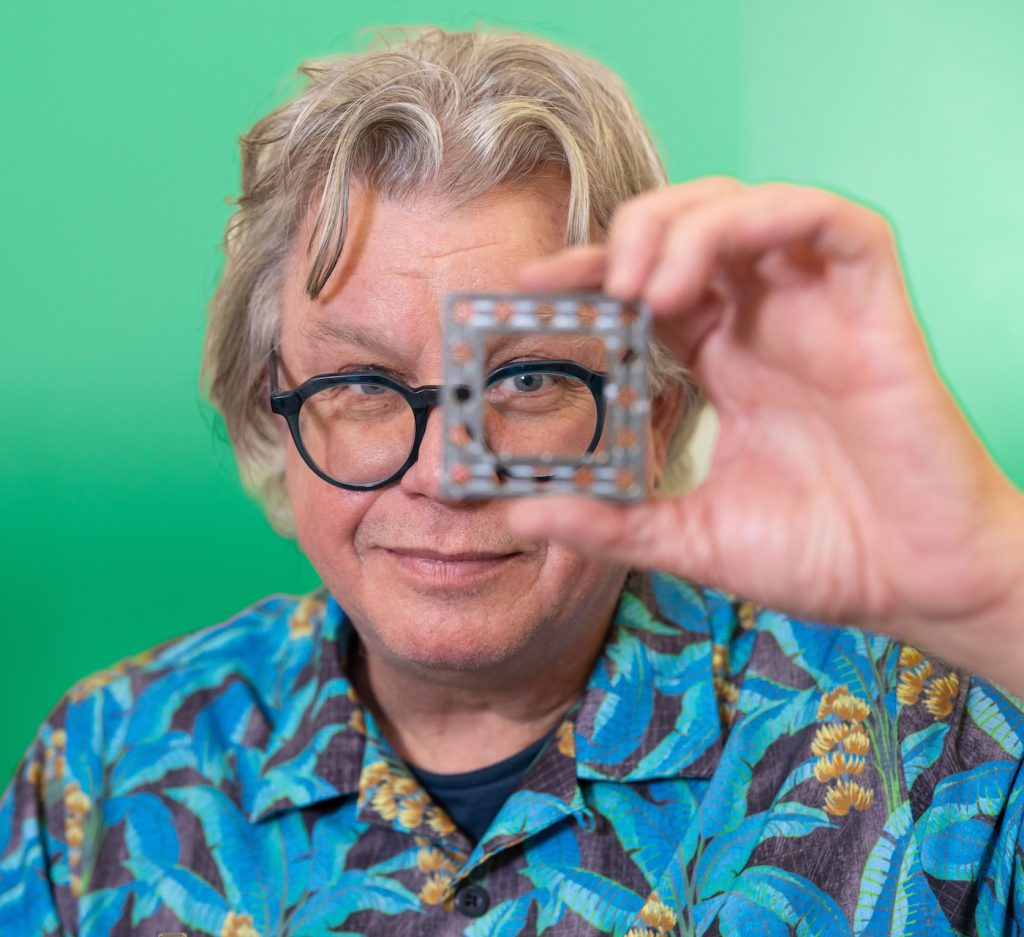

One toolkit of components Smith and his colleague Stephen Howard invented, called “MechBlock Kits,” provides fixturing, motion control and prototyping solutions to the end user at their own site. The series of modular blocks and bearings are used in building precision mechanical engineering systems to assemble devices and structures, especially those for precisely controlling movement. Smith’s innovation allows engineers to build systems faster and cheaper — and rebuild them without added expense when design changes are needed.

Other projects led by Smith focus on designing instruments and machines for advanced circuit manufacture to support electronics and semiconductor industries by better understanding how the material silicon can be used.

“This is what’s supporting the world right now.”

“Silicon, the primary material in computer chips and integrated circuits, is more essential than any other material in devices that use computers that form the brain of modern devices like phones and cars. This is what’s supporting the world right now,” said Smith as he holds a ten-inch long sheet of silicon. “If it’s not positioned correctly when it is repeatedly placed in processing machines to grow the circuits on its surface, the semiconductor is not going to work. It is this performance in manufacturing that produces computers with the capabilities we depend on in this computer age.”

Smith’s career has centered on nanotechnology research, which includes more than $2 million in funding from agencies such as the National Science Foundation, NIST, and the University’s Center for Precision Metrology industry affiliates program.

“Stuart Smith is a leader in transformative research and it is exciting to see that he is now being recognized internationally by NAI as well as the engineering and innovation communities,” said Rob Keynton, dean of the W.S. Lee College of Engineering. “He has advanced the field of micro sensors, providing the manufacturing industry with design mechanisms that can be controlled with precision and accuracy at the atomic scale. His research has been commercialized, resulting in three North Carolina companies as well as patents in both the U.S. and Europe. UNC Charlotte is proud that Stuart has centered his research here and is leading future generations with his innovative spirit.”

With fewer than 2,500 worldwide, the NAI Fellows now include three UNC Charlotte faculty members, two of whom were previously elected to this elite group.

- Ishwar Aggarwal, research professor in the Klein College of Science, a pioneer of infrared transmitting optical materials, chem-bio sensors and high-strength transparent materials

- W.S. Lee College of Engineering Dean Rob Keynton, a leader in developing biomedical micro electromechanical systems and microfluidic systems

As NAI Fellows, these Charlotte faculty members are in the company of 170 senior leaders of research institutes, about 60 inductees of the National Inventors Hall of Fame and 59 Nobel Laureates, among other awards and distinctions.

Collectively, NAI Fellows hold more than 86,000 issued U.S. patents, which have generated over 20,000 licensed technologies and 4,000 companies, and created an estimated over 1.4 million jobs. In addition, over an estimated $3.8 trillion in revenue has been generated based on NAI Fellow discoveries.

The 2025 Class of Fellows will be honored and presented their medals by a senior official of the United States Patent and Trademark Office at the NAI 15th Annual Conference in June 2026 in Los Angeles.

Learn more about Smith and the nomination.

Learn more about the 2025 cohort of elected NAI Fellows.