Engineering “UrbanEden” – UNC Charlotte’s Solar Decathlon House

The students designed and built several engineering innovations into “UrbanEden,” UNC Charlotte’s Solar Decathlon house. The integration of these innovations made each more efficient, which caught the notice and praise of the judges, who named UrbanEden one of the best engineered houses in the international competition.

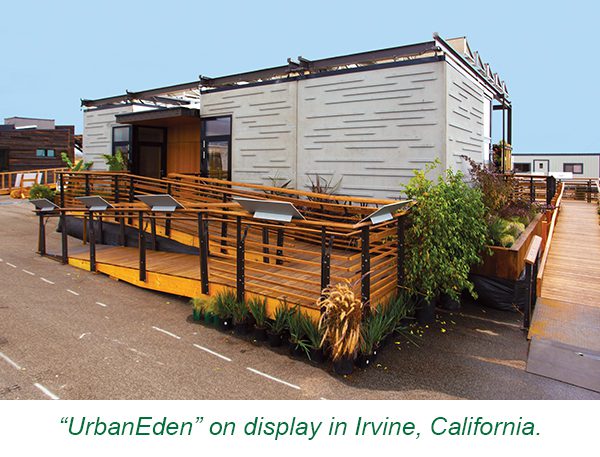

The UNC Charlotte house placed third in the engineering category of the competition, being recognized for its geopolymer concrete walls, capillary-tube cooling system, and moveable racks of photovoltaic panels. UNC Charlotte was one of 19 academic teams participating in the Solar Decathlon competition held this fall in Irvine, California. The competition included academic teams from around the world who built net-zero energy solar-powered houses.

“The judges liked our innovation and they were particularly impressed by how the systems complemented each other,” said Dr. Valentina Cecchi, one of the engineering team mentors and an assistant professor of Electrical and Computer Engineering at UNC Charlotte. “The concrete walls, the capillary tube system and the moveable solar panels all relied on each other for peak efficiency.”

The interdisciplinary UrbanEden team was made up of engineering and architecture students and faculty members. On the engineering side, about 35 students participated at different levels of involvement and times during the year-and-a-half-long project. Some of the students graduated during the course of the project, and were then hired fulltime to manage the completion of the house. There were also two senior design projects related to UrbanEden, one designing and building the energy-management, controls and monitoring systems, and the second working on the mechanical and electrical aspects of the solar panels and the design of the mechanical systems to achieve home comfort levels.

“One of the biggest challenges in the engineering of the house was designing it all to be transportable from North Carolina to California,” Dr. Cecchi said. “This was made more difficult because of the weight of the concrete walls. Our solution was to design the house as four modules that could each fit on a separate flatbed trailer.”

The size and interdisciplinary makeup of the team were also challenges.

“There were so many people working on different aspects of the project that it was a challenge to get everyone communicating and on the same page,” Dr. Cecchi said. “It was a very dedicated group, though, and the last few weeks everyone was working around the clock to get everything done.

“We are very proud of our team. Just making it to California and competing was a huge accomplishment. Finishing third in engineering was a bonus. We also won the People’s Choice Award, which showed that people liked the house and felt it was comfortable and livable. It also showed we had a lot of support back home, as well as in California.”

The three main engineering aspects of the house are:

- The geopolymer concrete walls that uses a fly-ash mixture to completely replace Portland cement as the binding agent. The use of fly-ash results in up to 90% reduction in associated carbon emissions.

- There is a capillary-tube radiant cooling system within the walls. The theory behind this hybrid passive/active cooling system is that the concrete walls absorb heat during the day, and this heat is flushed out by running water through the tubes within the wall. The water is moved through the capillary tubes to copper fin heat exchangers above the roof where it is passively cooled.

- A movable solar photovoltaic panel rack, which can provide shade or allow in sunlight during the day as needed, and move to expose the roof so the capillary tubes can be cooled at night.