Cybersecurity Double Take

As a doctoral candidate at the University of Connecticut, Aidan Browne made a career decision. Academia would be his path forward — but only after gaining industry experience in a manufacturing environment.

“The best professors were the ones having first done great work in industry,” he said. “I wanted to be one of them.”

With a Ph.D. in biomedical engineering completed, Browne went to work for Hamilton Sundstrand Space Systems International. In his role as a senior electrical systems engineer, he was part of a team that developed and created two life support systems for the International Space Station: the Oxygen Generation Assembly and the Water Processor Assembly. Next came an internal shift to a division where his work as a systems engineer included using cutting-edge technology to solve challenges that could be encountered by Joint Strike Fighters, among the military’s most sophisticated aircraft.

“This is where I gained real manufacturing experience,” Browne said.

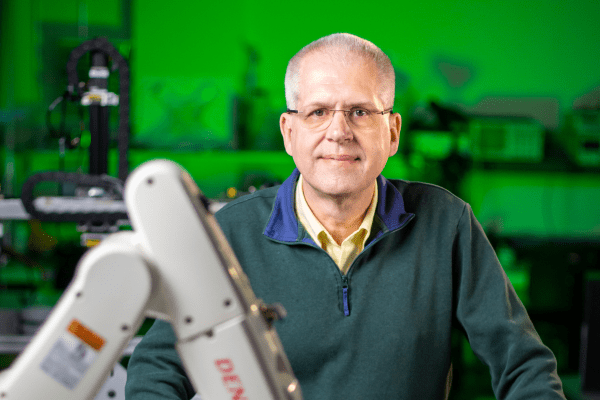

After one more industry stop at General Dynamics, which had recruited him to Charlotte to help produce biological and chemical defense products for the U.S. military, Browne made the move he’d eyed since graduate school — specifically, to UNC Charlotte. Now an associate professor of electrical engineering technology, he also directs the Master of Science in Applied Energy and Electromechanical Engineering program.

“The time was right,” he recalls.

Cyber Crime Fighters

That was in 2012. Since his arrival, Browne and his team have further sharpened their expertise through increasingly complex cybersecurity research opportunities funded by a number of federal sources (see sidebar). Now, he and his colleagues are leveraging their collective knowledge to develop solutions to the most real of threats faced today by manufacturers across industries — cyber attacks.

From IP theft and insider threats to ransomware and supply-chain attacks, U.S. manufacturers must proactively identify vulnerabilities in their computer networks that make them susceptible to external or internal cyber attacks — and be prepared to combat and mitigate them.

“The most effective way to test the security of a company’s network is to understand the potential damage a cyber attack could do,” said Browne. “The question has been how to do that without harming an entire network and operation.”

Virtual Breakthrough

From the team’s cumulative research and practical experience has emerged the know-how to build a virtual copy of a company’s computer network after performing a complete audit of it. From a set of custom-built servers they call “the cyber physical range,” the team can attack the copy to determine the original network’s strengths, weaknesses and vulnerabilities, while keeping the actual network safe.

“What our work offers that other similar cyber range projects do not is an ability to directly include pieces of manufacturing systems that typically are not virtualizable,” said Browne. “What’s the point if you can’t test the entire network and detect every possible vulnerability? We have found a way to tap the pieces of hardware — physically and remotely — that are impossible or inconvenient to virtualize.”

Building on this groundbreaking capability is the development of “digital twinning” to accomplish something similar for detecting vulnerabilities in equipment on a manufacturing floor. Through a grant from Chicago-based MXD, a consortium that focuses on strengthening American manufacturing, Browne and Wes Williams, associate professor of electrical engineering technology, create the twin — a digital representation of a product, system or process used for simulation, testing, monitoring and maintenance — to be attacked and observed virtually without harming real equipment or shutting down operations.

“For example, we’re able to virtualize a robot arm so on screen you can see it moving just like the real one,” Browne explained. “So now, we can cyber attack the program in the twin as it makes parts — and see all the ways a bad actor might alter that part ever so slightly, not visible to the human eye, but enough so that the change would affect the ability of a manufacturer to produce safe, high-quality and usable products.”

A second round of funding from MXD is pending for a partnership with Charlotte-based Siemens to produce a digital twin of the tech giant’s software on real hardware.

Building Cyber Expertise in Manufacturing

UNC Charlotte faculty have developed in-depth expertise — and built a national reputation — around successful government and privately funded projects that meet critical national security needs. Among them are:

U.S. DEPARTMENT OF LABOR/MISSION CRITICAL OPERATIONS

As part of a total $35 million to a consortium of North Carolina institutions, Charlotte received a $1.5 million grant to update and optimize a system for responding to emergency technology needs at data centers that operate 24/7/365 in an environment where highly trained technology experts are scarce. The solution: Set up centers where specifically trained technicians respond to requests from partner agencies and corporations when they need support. This way each organization can access the help it needs without having to individually employ a team of experts.

NATIONAL SECURITY CENTER/SECURING AMERICAN MANUFACTURING

Based on the success of Mission Critical Operations — and the resulting infrastructure at Charlotte — the National Security Center identified Charlotte to partner with Los Alamos National Laboratory and the Y-12 National Security Complex for a project to secure the manufacturing chain for the U.S. Department of Defense and the U.S. Department of Energy. Along with federal contractor Consolidated Nuclear Security, Charlotte faculty members developed systems to deter attempts by unauthorized parties to gain access to the country’s nuclear materials or related facilities.

LOS ALAMOS NATIONAL LABORATORY/SECURING MANUFACTURING OPERATIONAL TECHNOLOGY

Now working directly with Los Alamos, Charlotte continues working toward securing the highest levels of American manufacturing with a four-year, $2 million contract that is supporting ways to vet hardware brought into federal facilities to service equipment and similar tasks

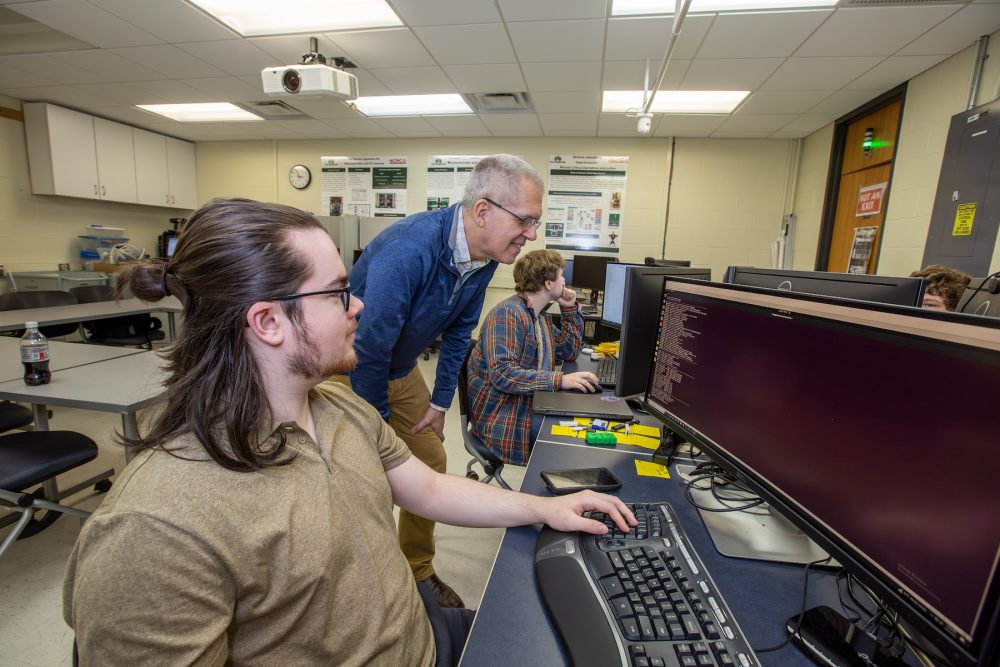

Next Gen Cyber Experts

Strikingly clear against a backdrop of rapidly growing need is a shortage of students to populate the next generation of manufacturing cybersecurity professionals to meet the high demand. The experience of graduate students from the William States Lee College of Engineering and the College of Computing and Informatics who have opportunities to participate in faculty-led research — and take advantage of internships with federal agencies — is regarded as highly valuable not only by the students but those in the field.

Joseph Tindall ’21 ’23, a graduate researcher in Browne’s lab, graduated in May with a master’s degree in applied engineering and electromechanical systems. Originally intending to work in robotics, he pivoted as a result of his research experience toward options that will allow him to “… combine an engineering mindset, a desire for automation and a joy of working with computers.” Now a systems engineer with FOX Sports, he is eager to delve into his career and explore further certification opportunities.

“While some master’s degree programs are general in nature, the electromechanical focus at Charlotte shines like none other,” Tindall said. “It provides a specialization that opens understanding to a multidisciplinary approach, which will prepare me for eventual leadership positions. I will continue to develop and hone my skills; lifelong learning will keep me pushing the envelope of innovation.”

Browne explains that due to the proprietary nature of protecting government computer networks, internships and jobs often require participants to be U.S. citizens, making many international graduate-level students and faculty members ineligible for contracted work.

“We can’t produce these folks quickly enough,” he said. “A primary message is ‘We need more American students to enter these fields.’ There are challenging, high-paying and rewarding careers waiting for them.”

Article written by Susan Messina, director of strategic content for University Communications.