UNC Charlotte is first public university in the U.S. to open Super Fab Lab

Advanced manufacturing and engineering focus establishes lab as unique resource for Charlotte

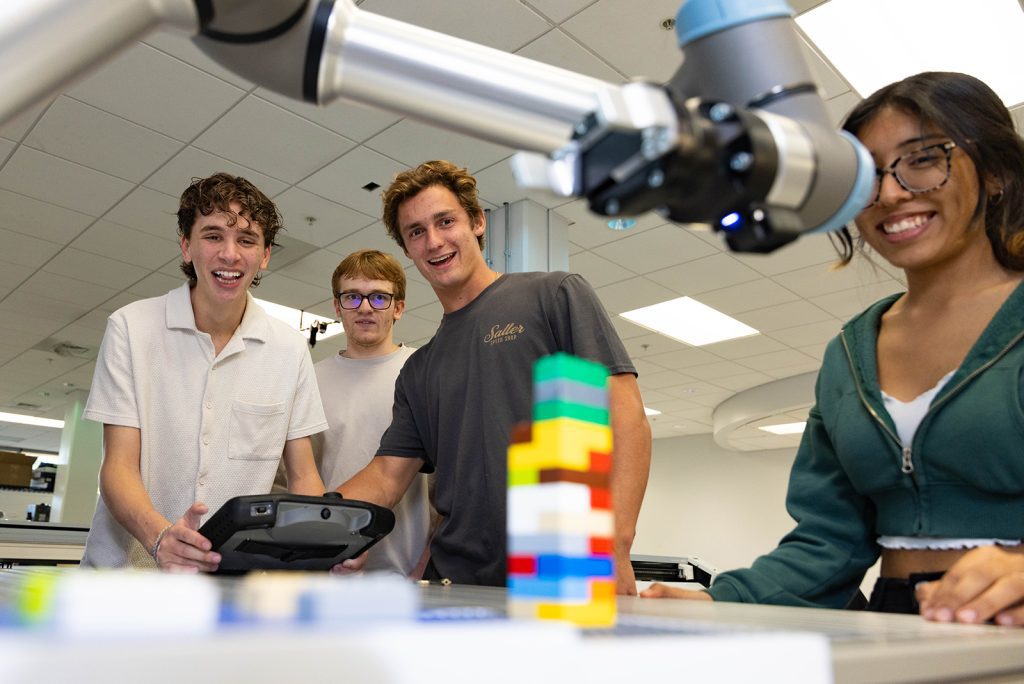

UNC Charlotte has become the first public university in the U.S. to establish a Super Fab Lab, a designation by the non-profit Fab Foundation. This novel resource, led by the William States Lee College of Engineering in collaboration with the College of Computing and Informatics, will provide undergraduate and graduate students an even deeper experiential learning opportunity. On Tuesday, April 15, faculty and staff from these two colleges toured the facility during an event designed to introduce them to the equipment and capabilities.

Since only six facilities worldwide are recognized as Super Fab Labs, Charlotte’s addition has helped the university join an elite group of creative inventors and developers. Fostering this type of creativity, and prioritizing added value to the manufacturing industry, led Charlotte to invest in the infrastructure needed to pursue and obtain a Super Fab Lab. Additionally, the Super Fab Lab global network will give Charlotte students and faculty access to a digitally connected forum of like-minded researchers, makers and innovators, facilitating and streamlining the advancement of technology and ideas.

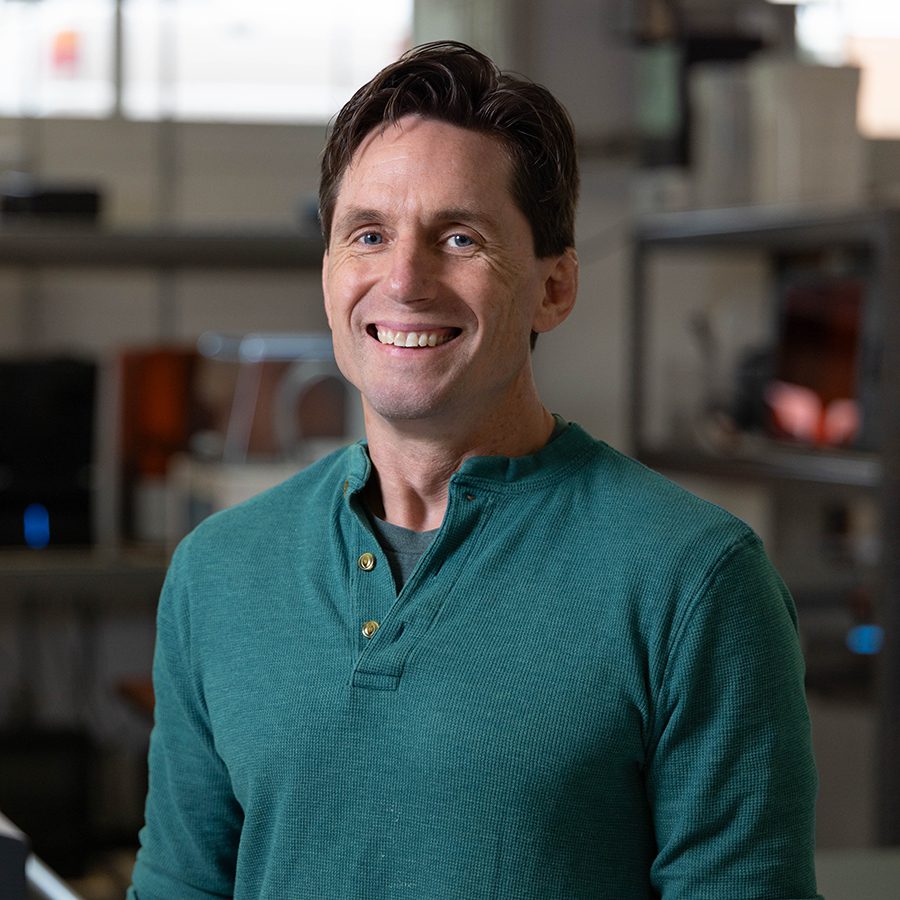

Terence Fagan Ph.D., associate teaching professor of mechanical engineering and engineering science, is the lab’s founding director.

Early in the COVID epidemic, Fagan and colleagues across campus and the Charlotte community designed a personal protective device for the medical community. Using University and community 3-D printers, they produced face shields for hospital workers and first responders, averaging 100 per day. Later, using industrial partners and injection molding machines, they produced more than 100,000 in total. Their process did not get slowed down by the traditional, complex industry process.

While this face shield was a relatively simple design, Fagan realized the larger implications of expediting the manufacturing process.

“We need to break down barriers in the academic world and help bring manufacturing back to the United States,” said Fagan. He began exploring the Super Fab Lab concept as a way to mitigate the traditionally long production cycles of factory floors.

“With the Super Fab Lab, our students can be more agile than industry,” said Fagan. “It puts the power in the students’ hands so they can reach a final product much faster than traditional methods.”

Students are central to the Super Fab Lab process

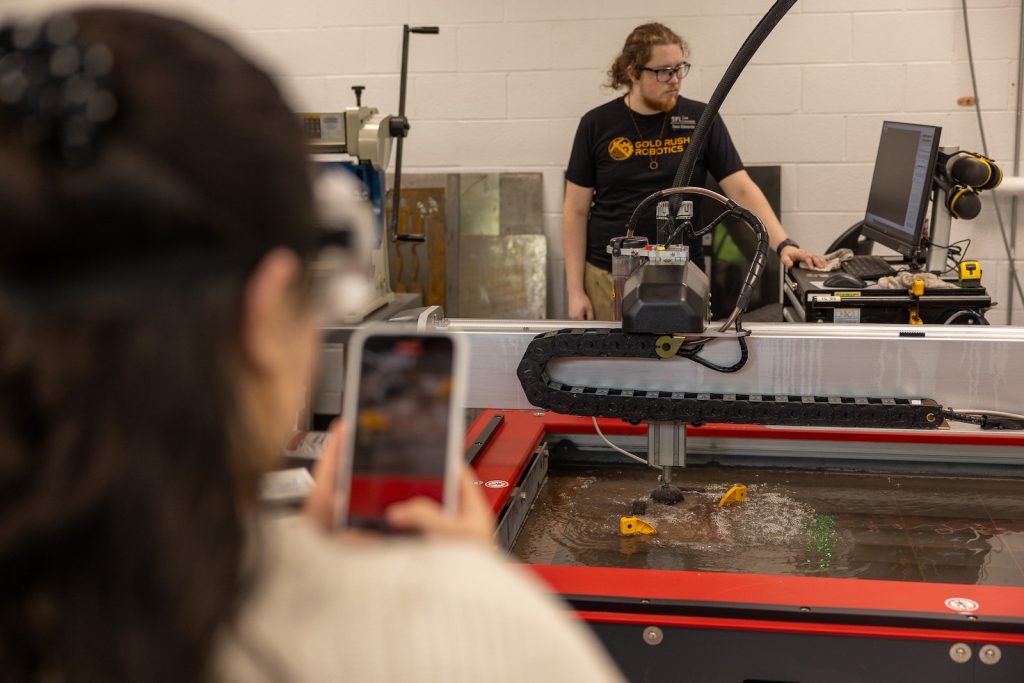

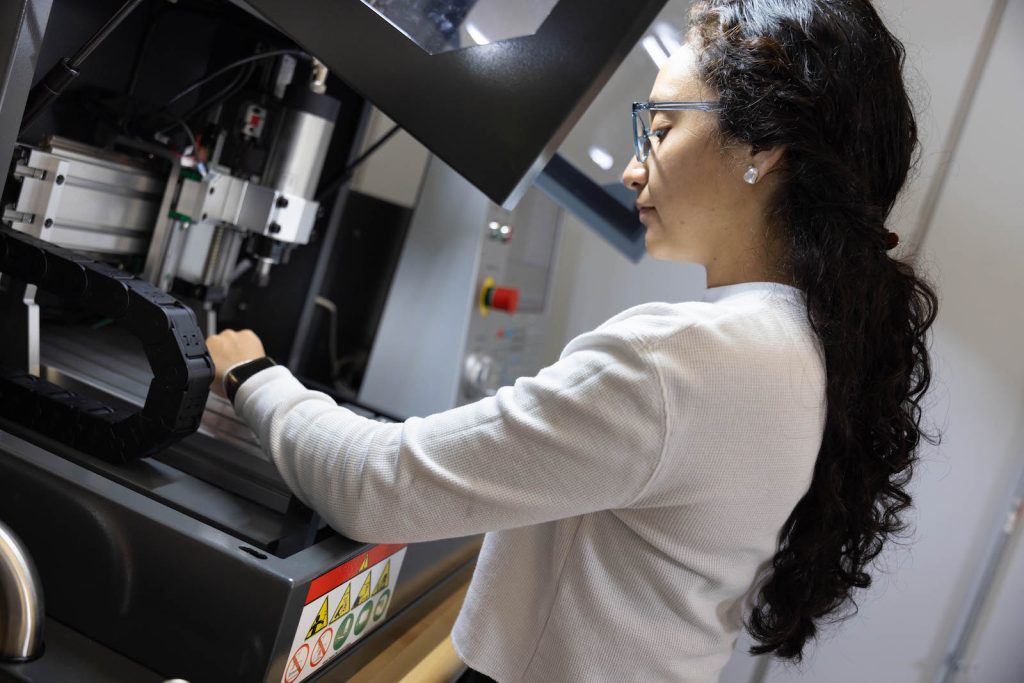

Students are key to the Charlotte Super Fab Lab, not only gaining hands-on learning, but also helping make decisions about the equipment, space and processes. At Charlotte, several engineering and computer science students already work in the lab, finishing installation of the final pieces of equipment, recommending policies, documenting procedures and testing machinery for early projects. They are extensively trained to operate the machinery in order to train other student users.

These Niner Engineers are cultivating the vision of the lab by keeping a permanent seat on the steering committee, meanwhile connecting with the other six Super Fab Labs and 3,000 Fab Labs around the globe to share best practices and perpetuate an innovation culture.

Berenice Chavez, a mechanical engineering student who works in the facility, said, “The idea of putting lessons into practice has been my core motivation. I know I am not just learning the science of it all – my university has the resources, equipment and a team to help me expand my learning. It is a privilege to work along with my classmates, my friends, to see what we can create together.”

While students have a strong hand in the lab, they also are supported with guidance from faculty of the two driving colleges. David Wilson, Ph.D., professor of software and information systems in the College of Computing and Informatics, serves on the lab’s steering committee and provides insight for its students.

“The Charlotte Super Fab Lab is an incredible resource for UNC Charlotte, offering invaluable learning opportunities for students and faculty alike,” said Wilson, who has also been instrumental in other digital fabrication initiatives, such as his college makerspace that opened in 2016. “The amazing creations and collaborations the Super Fab Lab will help bring to life will expand the horizons in our University’s mission to advance innovation for the benefit of society.”

The Charlotte Advantage

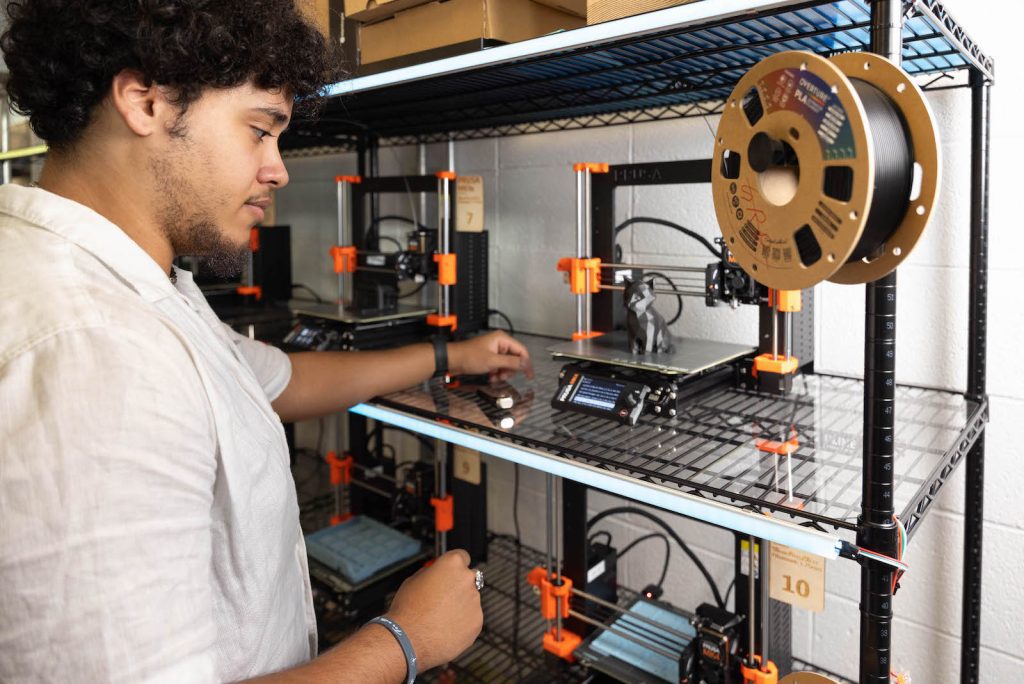

UNC Charlotte took the Super Fab Lab concept a step beyond the standard model by including a specialty focus area in its purpose: adding value to the manufacturing industry. Students will gain extensive knowledge by experiencing first-hand the complete manufacturing process from ideation to industry-grade product.

By having a variety of equipment from entry-level to professional-grade allows UNC Charlotte to democratize the manufacturing process, giving students the opportunity to streamline and optimize their technical, hands-on skills. Common barriers for students, such as lack of equipment or funding, are removed from this model, allowing for enhanced creativity.

Responding to the regional workforce demands

The greater Charlotte region and its 3,600-plus manufacturers can take advantage of the highly skilled graduates who have obtained experience operating the Super Fab Lab’s advanced equipment.

In addition, through a funding agreement, local companies will also be able to access Charlotte’s resources themselves, helping improve workflow and accelerate their manufacturing process. Small businesses in particular can benefit from the reduced barriers. For example, machines typically only enjoyed by larger organizations will be available to smaller businesses through the program, facilitating their use of manufacturing equipment, including CNC-milling, precision metrology and circuit production machinery.

Rob Keynton, Dean of the William States Lee College of Engineering, secured funding for the Super Fab Lab from Engineering North Carolina’s Future, a 2022 initiative by the North Carolina General Assembly. The initiative provided UNC Charlotte with appropriations to create state-of-the-art, collaboration-inspiring learning and research spaces; develop innovative, industry-supporting programs; and attract world-class faculty.

After several years of planning, work to construct and equip the UNC Charlotte Super Fab Lab began this past August. Temporarily located in the basement level of Kennedy Building, Charlotte’s Super Fab Lab is initially being used by students in the William States Lee College of Engineering and the College of Computing and Informatics.

The lab will roll out the welcome mat to more students when it eventually relocates to its permanent location in the Burson Building, following completion of renovations.