AREVA Power Systems Teaching Laboratory

With experiments ranging from the principles of basic electromagnetism to the integration of renewable power systems into the grid, the AREVA Power Systems Teaching Laboratory in the UNC Charlotte Energy Production and Infrastructure Center (EPIC) building provides students hands-on learning tools that teach the many properties of electric generation and use.

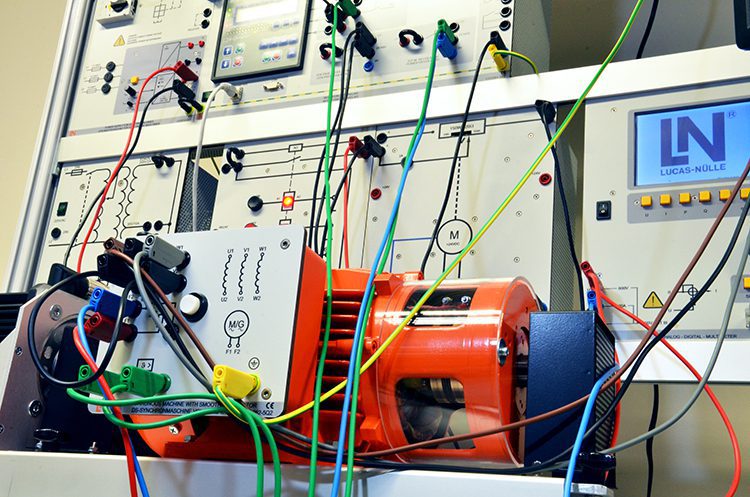

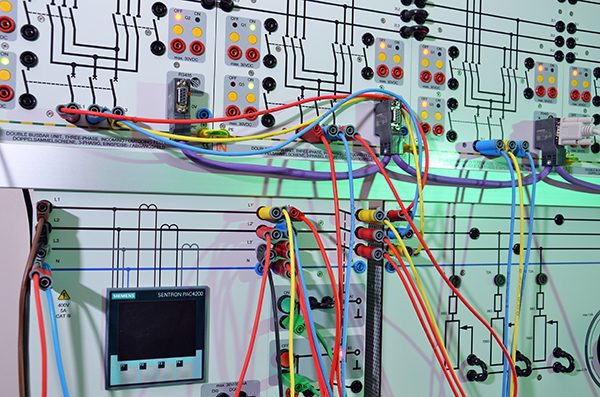

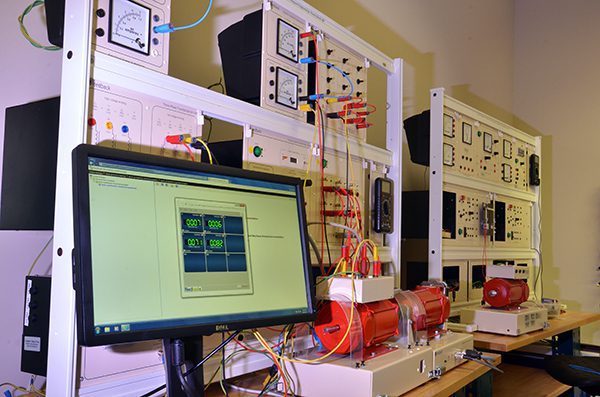

The 17 work stations in the lab include test benches to teach power system components, transformers, protection, control, SCADA, electronic motor drives, power electronics and electrical machines. The hardware in the lab is from Lucas Nülle and Feedback Systems. The main financial supporters of the lab are AREVA and the State of North Carolina.

“The AREVA lab is completely dedicate to teaching, primarily at the undergraduate level,” said Dr. Johan Enslin, director of EPIC. “The lab is all about hands-on learning. Through the experiments they perform in this lab, students can immediately see the results of the actions they take and variables they change. It is a fantastic learning tool.”

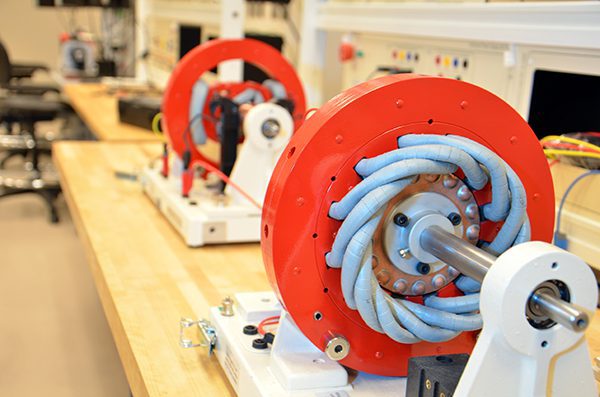

Laboratory equipment includes electromagnetic trainers, reconfigurable motors and generators, electronic motor drives, and systems to simulate protection of transmission lines, busbar systems, motors and generators. Simulation and testing capabilities include interactive power systems, drives and power electronics, traditional and renewable generation, transmission and distribution, energy storage and fuel cells, and smart energy meters.

“We start with basic electromagnetic principles,” said Dr. Alec Martin, a faculty associate in Electrical and Computer Engineering and manager of the lab. “Students pass a current through a wire and with a small compass can see that it creates a magnetic field. From there they go the bench that teaches about transformers, voltage, single-phase and three-phase power. Other benches teach synchronizing AC current on the grid, DC motors, photovoltaic use, the impact of wind turbines, and the simulation of 150 miles of transmission line.”

Also taught is the power industry’s dedication to safety. “Overall in the lab, safety is fundamental,” Dr. Martin said. “All experiments must be properly grounded, all setups must be double checked by two people, all safety covers must be in place on rotating machines, everyone must wear shoes, and there is no food or drink in the lab.”

To optimize the equipment and experiments in the lab, a senior design team is currently developing a number of laboratory modules focused on electric machines, power generation, transmission and distribution, and protection. The team is characterizing all of the lab equipment, developing appropriate industry models and integrating standard analysis software such as ETAP.

For more information contact Dr. Alec Martin.