Capturing CO2 in Concrete

Capturing carbon dioxide before it enters the atmosphere is crucial to reducing greenhouse gases. A challenge that arises once the CO2 is captured is how to store it safely. Dr. Shen-En Chen and his students are developing porous, calcium-rich concrete mixtures that can not only absorb the gas, but actually render it inert.

A professor of Civil and Environmental Engineering at UNC Charlotte, Dr. Chen has been working on various carbon sequestration techniques since 2000.

“Global warming has been tied to atmospheric carbon dioxide accumulation,” Dr. Chen said. “Sixty percent of the CO2 has traditionally come from coal-fired power plants. These plants are reducing their emissions by capturing CO2 with scrubbers and storing it in tanks. The challenge now is to develop a more permanent storage solution to supplement the tanks.”

One current method for storing CO2 is to pump it into oil well reservoirs where it can be stored and at the same time used as a catalyst for maximizing oil production. There are now about 100 such CO2 storage ground wells in the United States, but direct environmental impacts have not been quantified.

In Scandinavia, researchers are developing techniques to store CO2 on the bottom of the ocean. The theory is that the water pressure of the ocean will hold the CO2 in place. There are concerns about the CO2 escaping, and some early experiments are showing increased acidity in water around the storage sites.

“At UNC Charlotte we’re trying a third method, which is to stabilize the CO2 by putting it into cementitious form,” Dr. Chen said. “CO2 is added to a calcium rich mix, where it is consumed during the curing process. The solidified mass can then be as an engineered building material.”

Funding for the research comes from the Chinese National Natural Science Funds for Young Scholars. The three-year study will investigate the enhancement of physical and chemical CO2 sorption mechanisms.

A challenge of working with CO2 is that the captured gas must be brought under high pressure to compress it to a liquid. This pressure has to be maintained, which means underground wells must be capped properly or pumped continuously.

“With our method,” Dr. Chen said, “we only need pressure at the initial stage of injecting CO2 into a slurry, where calcium stabilizes the carbon. The carbon is then entrapped in the porous medium.”

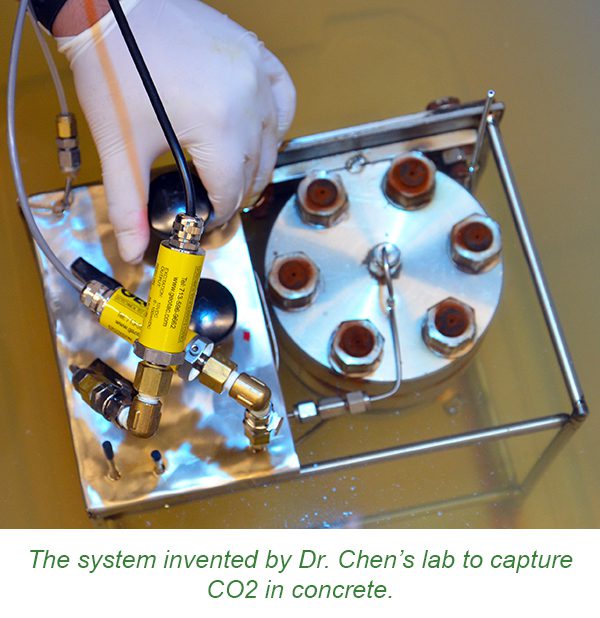

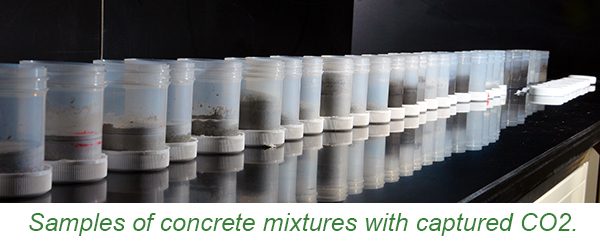

To develop optimal mixtures, Dr. Chen and his Ph.D. students designed and built a system that can keep the CO2 pressurized while it is added to a laboratory specimen. To date, the team has made and is testing several samples of varying composition.

“One vision of our research is to produce concrete with an optimized balance of sorption rates and building material strength,” Dr. Chen said. “We are also adding various chemicals to the mixture to improve the stability and promote the absorption of the CO2. The chemistry and physics are very complicated.”

In addition to storing and breaking down the liquefied CO2 that is mixed in, the concrete also has the ability to naturally absorb CO2 from the air. This means a road built from the concrete could absorb the CO2 being produced by the cars driving on it. One use the Chinese are proposing for the concrete is to use it as backfill for coal mines, where it can stabilize the structure of the mine and absorb CO2 released from the coal.

“There are many benefits and uses for the material,” Dr. Chen said. “We first have to optimize the methods for producing it, so it can be a viable business model that can be deployed on a large scale.”

For more information contact Dr. Chen.