Engineering Better Ovens a Piece of Cake

An engineer’s cake recipe

Start with 50 cake mixes, stir in 162 eggs and three gallons of vegetable oil, then add 32 thermocouples and bake at 350 degrees until you get the data needed to verify your computational fluid dynamics analyses.

The cake recipe, along with the toasting of 12 loaves of bread and the baking of 20 pounds of potatoes, was part of a senior design project to improve the evenness of heating in commercial ovens for ITW Cooking Equipment. ITW (Illinois Tool Works) is the holding company for Vulcan-Hart/Wolf Range Company, which manufactures cooking equipment such as ranges, fryers, ovens and griddles for restaurants.

Robert Dunn, a Production/Lab Engineer with ITW and a Lee College of Engineering alumnus (MEES 1995), brought the project to the Senior Design Program. “I had done senior design when I was in school, so I knew a little about the program,” Dunn said. “I got some more information off the web and then talked to some people here about sponsoring a project. We decided this was a great way to get some time-consuming research done and at the same time give back to the community by sponsoring a project.”

The project of analyzing the evenness in heating of a convection oven and then designing and building an improved prototype involved a lot of up-front computational fluid dynamics (CFD) and then a lot of testing.

“It takes a lot of time to do modification work on an oven and then test its performance,” Dunn said. “So we knew it would be better to do CFD predictions to see how air is moving in the ovens. We were thrilled to get Dr. Uddin as the mentor for the project because of his expertise in CFD. We were also very happy with the project team in that we got David Hunter as the student leader. David had worked here before and knew our company and products.”

The student team was made up of mechanical engineering seniors David Hunter, Cameron Auten and Nicholas Ertel. Hunter had worked part time for ITW in 2008 and done a summer internship with the company. The team’s faculty mentor was Dr. Mesbah Uddin, whose research specialty is fluid dynamics.

Being involved in the project to improve the ovens was interesting and challenging, Hunter said. “The movement of the air is a critical factor, so you have to figure out how to move air evenly. But that movement depends on what you’re cooking. You can get bread to brown evenly, but then you can cook potatoes and because of all the moisture in them you get totally different air movement.”

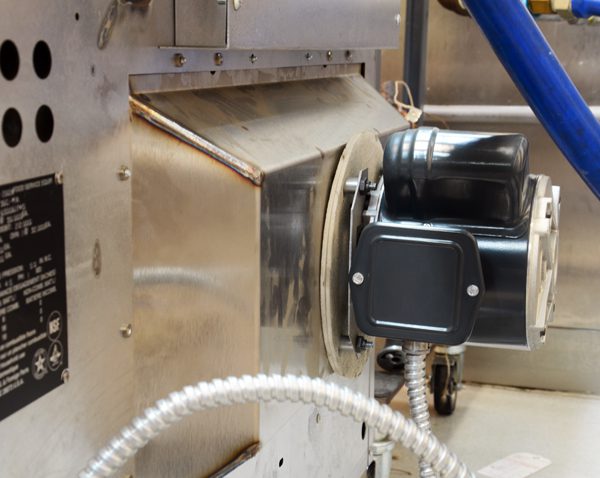

The ITW forced-air convection oven they worked on has burners surrounding the side oven walls that do the heating, and a blower in the back to move the air. Based on the team’s CFD analysis, they developed an air movement solution that involves moving the blower back into another new compartment of the oven and then adding more holes in a new pattern to the back plate.

“This was a good solution,” Hunter said, “because the modifications can be done without changing the production line. It’s just the addition of an extension to the back plate and the drilling of some holes.”

The proposed oven modifications were made and then the team began testing to see if the CFD predictions were correct. This is where the baking of cakes and toasting of bread came into play.

“The bread toasting is essentially a visual test,” said team member Cameron Auten. “We put pans of bread on all the oven racks, cook them, and then look to see how evenly all the pieces have browned.”

The cake tests are a little more complicated. Along with having to make all the cakes, the team had to deal with multiple thermocouples inside the oven.

“We had worked with thermocouples in labs at school, but the most we ever used was two,” Auten said. “So dealing with all the wires and hookups for 32 thermocouples was a real challenge. But we did it and got the data we needed down to a 10th of a degree.”

The team’s design solution did prove to be successful, and ITW will now consider how best to implement the recommendations.

“The project was a real win-win,” Dunn said. “We got some very good results and the students learned a lot. This has been a great way for ITW to practice our commitment of being good stewards to the community and supporting education. We hope to continue the relationship with UNC Charlotte and sponsor some other projects in the future.”

The project experience was also beneficial for ITW finding a good employee and Hunter finding a job. “We have been very impressed with David and his work ethic,” Dunn said. “So, we’re hoping to hire him when he graduates.”

William States Lee College of Engineering Senior Design Program