Fire Safety Project with DHS

The Effectiveness of Pre-Applied Wetting Agents in Prevention of Urban Wildland Interface Fires research project was funded by the Department of Homeland Security through the Assistance to Firefighters grant in Fire Prevention and Safety (Performance Period 8/22/08-8/21/11).

Here you will find information on the research project that we hope is helpful to you and your endeavors in dealing with the Wildland Urban Interface.

Front Row (l to r): Aixi Zhou, Jeff Kimble, Robby Myers, Palak Desai

Back Row (l to r): Dave Murphy, Dustin Reynolds, Layna Nelson, Richie Bingler, Joe Urbas

Project Overview

THE PROBLEM

Wildland Urban Interface (WUI) fires have become a serious problem affecting most notably California, Colorado, Arizona, Texas and numerous other states in the United States. This is not only a regional concern but noted to occur all over the world. Some of these fires result in catastrophes destroying a large number of buildings. Three recent examples in the United States include the “Tunnel/Oakland” fire in Oakland, California in 1991 that destroyed over 2900 homes; the “Old, Cedar, etc.” fire in Southern California in 2003 that destroyed over 3,640 homes, and the “Witch, Slide, Grass Valley, etc.” fires in Southern California in 2007 that destroyed over 2,180 homes.

Numerous catastrophic WUI fires in recent years have led to firefighter deaths and injuries related to heat and smoke. Most fire ground deaths in 2006 occurred in wildland[1] fires, with 16 deaths or 42% of all fires [1]. Seven firefighters died in wildland fires in 2006 due to entrapment in fires. Most fatalities and injuries to firefighters occur from exertion and stress, which typically happens in situations where firefighters are understaffed in sudden large fires. Also, casualties and injuries can occur when firefighters are trapped by fire progress.

Firefighting in WUI areas is extremely difficult due to differences in training and equipment between structural firefighters and wildland firefighters. The wildland firefighters are trained to use approaches that prevent the spread of the fire (defensible space), and structural firefighters are trained to fight structural fires. In severe WUI fire circumstances, such as when entire neighborhoods are involved, the size of these fires typically overwhelms structural firefighters. They can save only a few buildings out of many [2, 3, 4].

Various mitigation approaches that have been developed rely on the creation of defensible space around structures, and recently on the use of ignition-resistant building materials for the outside of structures. The success of this approach depends on the degree of compliance with regulations, maintenance of the defensible space, the presence of firefighters, and the availability of suppressants at the time of the fire. Also, the regulation requirements vary by area, and some requirements (ignitability of building materials) only apply to new structures. In many areas, the requirement for the creation of defensible space is not popular because residents do not want to modify the natural environment and landscaping around their structures.

A dangerous situation for firefighters can be caused by a significant difference between the effects of flame radiant exposure on wood and other external building materials and humans. Humans can feel pain or get burned quickly from relatively low radiation exposures (6.4 kW/m2 causes pain on exposed skin after 8 seconds [5], and 7 kW/m2 is the maximum estimated exposure for a firefighter wearing wildland firefighting clothing and head and neck protection over a period of approximately 90 seconds [6]). Siding and roofing materials typically ignite at much higher radiation exposures, and at much higher exposure times (piloted wood ignition typically occurs at flux exposures of about 14 -18 kW/m2, and at times longer than 180 seconds [7]). Therefore, structural firefighters can easily get harmed when attempting to prevent homes from igniting.

In some cases, the use of pre-wetting of vegetation, dead fuels, and structures by using water (through sprinkler systems), foams, and fire-blocking gels (gels) has been found effective for preventing the spread of WUI fires to structures and ignition of structures [8]. Also, pre-wetting has been recommended [9, 10] and used [11, 12] during recent WUI fires. Previous experience has demonstrated that wetting agents and systems are capable of protecting structures in landscaped WUI environments and safeguarding firefighters by creating a wide enough space by sufficiently wetting dead and live fuels in the space so that the structures cannot be ignited or the spread of flames can be prevented.

References

[1] Fahy, R.F., LeBlanc, P.R., Molis, J.L., Firefighter Fatalities in the United States – 2006, NFPA, Fire Analysis and Research Division, June 2007.

[2] Butler, C.P., (1976) The UrbanWildland Fire Interface, Fire Prevention Notes, No. 10, California Department of Forestry, September 1976.

[3] Cohen, J. Preventing Residential Fire Disasters During Wildfires, US Department of Agriculture, Forest Service Research, Rocky Mountain Research Station, Fire Sciences Laboratory, PO Box 8089, Missoula, Montana, USA 59807.

[4] U.S. Fire Administration, Fires in the Wildland/Urban Interface, Topica; Fire Research Series, Volume 2, Issue 16, March 2002.

[5] Drysdale, Dougal. 1985. An Introduction to Fire Dynamics, Wiley-Interscience Publications, John Wiley and Sons, New York.

[6] Butler, B.W. and J.D. Cohen. Firefighter Safety Zones: A Theoretical Model Based on Radiative Heating. Int. J. Wildland Fire 8(2):73-77, 1998.

[7] Urbas, J. and P. Desai, Effectiveness of Pre-Applied Wetting Agents in Prevention of Wildland Urban Interface Fires, Proceedings of the 12th International Fire Science and Engineering Conference (Interflam 2010), July 2010 in Nottingham, UK, Interscience Communications Ltd., July 2010.

[8] Madrzykowski, D., NIST, and Bartlett, J., Fire Protection Inc., personal communications, March-April 1999.

[1] Separate statistics for WUI fires is not available.

THE PROPOSED SOLUTION

Correct application of wetting agents by fire fighters or others, and the use of self-contained pre-wetting systems could be an extremely valuable mitigation approach if applied correctly. This means a sufficient amount of a wetting agent needs to be applied at the right time to prevent ignition of fuels around structures and the structures themselves. Such systems could protect structures even without the presence of firefighters and could serve as an additional mitigation measure if the landscaping is overgrown.

The goal of this project is to reduce firefighters’ fatalities and injuries in UWI fires by providing a scientific basis for the optimal implementation of pre-wetting systems. The goal was achieved through systematic examination of the performance and effectiveness of three categories of wetting agents (water, foam, and gel) for UWI fire prevention, and developing engineering information and tools (including testing method and educational materials) for optically implementing wetting agents for UWI fire conditions. Specific objectives of this project are set to accomplish the following:

1. Develop a database describing the performance of water stressed live landscaping plants, dead fuels (dead grass and other vegetation), and building elements when wetted with water, foam, and gel at various times before firefront arrival at various weather conditions and exposed to UWI fire conditions as determined by various wildland vegetation fuels and their distances to landscaping plants and structures. The database will be used to develop engineering correlations that can be used to design wetting and extinguishing procedures and systems for preventing UWI fires from spreading to and igniting structures.

2. Develop a test method for the evaluation of the effectiveness of wetting agents applied to various landscaping plants and building assemblies, and initiate its standardization in ASTM.

3. Develop an educational module related to the use of wetting agents for UWI fire protection for fire service personnel, home owners and general public education.

The outcomes from this project are a database of performance and effectiveness of three types of wetting agents (water, foam and gel) in various WUI circumstances, a standard proposal to ASTM, and an educational module for fire service personnel and the general public.

REFERENCES

1 Cohen, Jack, The Wildland-Urban Interface Fire Problem, Forest History Today, Fall 2008, p. 20-26.

Procedures

SUMMARY

This research evaluated and quantified the performance and effectiveness of pre-applied wetting agents in prevention of wildland fire spread to landscaping plants and structures in the wildland urban interface… The project evaluated the fire performance of three categories of wetting agents (water, Class A foams and gels) on landscaping vegetation fuels surrounding structures and external structural materials, and assess the effectiveness of these wetting agents on ignition and fire spread prevention. The wetting agents were applied at various times prior to exposure fire conditions, and exposed to various drying conditions to evaluate their performance as a function of time and drying conditions that might be encountered prior to the fire front arrival to account for water evaporation and run off.

The evaluation and assessment was achieved through the determination of Critical Flux for Fire Growth (CFFG) on individual landscaping plants and building assemblies within three minutes of the heat flux (heat radiation) exposure from a radiant panel. The Intermediate Scale Calorimeter was used to provide the heat flux exposure. The CFFG was found by exposing the samples to varying heat fluxes until the flux was just sufficient to ignite and start fire growth within three minutes of exposure. The plants and the building assemblies were simultaneously exposed to a 300 mm pilot flame. The heat flux exposure simulated radiation exposures from wildfires, and the pilot flame simulated flaming from accumulated embers and other small fires started by embers and flying brands. The three minute exposure was used to simulate the relatively fast fire front passage time. .

The results of the intermediate-scale laboratory tests were then verified on a series of full-scale outdoor tests.

Data collected from these tests was used to develop a standard test method for evaluating UWI wetting agents on various substrates. The test method is currently being developed into an ASTM standard.

In addition, an educational module was developed that is herein being disseminated to fire services within North Carolina and nationwide. The fire service and building owners can immediately transfer the research results into special wetting agent purchasing decisions and firefighting tactics related to the use of wetting agents to increase the level of firefighter safety involving UWI fires.

EXPERIMENTAL

Intermediate Scale Tests

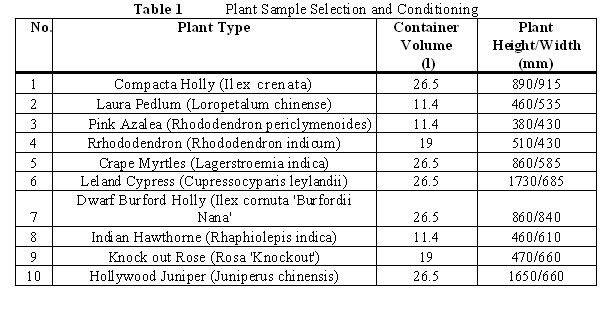

A survey was conducted among 10 nurseries in the southeastern states of the U.S with the objective to determine the most popular landscaping plants in this part of the country. Nine plants were selected for this research based on the results of the survey. One plant (Hollywood Juniper) was selected from the plants tested by Ettlinger10 who tested plants used in California, and found that this plant had the highest burning rate. The plants included in this project and the volume of the container and approximate plant dimensions are given in Table 1.

The plants were purchased in a local nursery. The plants chosen were the largest available at that facility. The plants were dried to about 25 % of the total plant water content, which represented barely alive plants representative of the worst case condition the plants would be in during a drought10. For comparison, one plant was dried completely, which represented about 10 % of the total plant water content (Compacta Holly). The plants’ water content was determined by weighing branches of the plants during the drying process. It was noticed that several plants dried non-uniformly, which might possibly affect the results of the measurements. However, it is not necessary that in nature the plants would always dry uniformly so this is only a limitation to consider.

Table 1 Plant Sample Selection and Conditioning

External Wall and Roof Constructions

The assembly used to test the building structures were to be created to be representative of those found commonly across the country. The external wall and roof assembly specimens (building materials) were 1000 mm x 1000 mm large. They were constructed by fastening a 12.7 mm thick oriented strandboard for walls and 19 mm thick oriented strandboard for roofs onto a wood frame made of 38 mm x 89 mm wood boards with two additional boards spaced evenly between the upper and lower frame member. The frame was made so that the shorter sides of the boards were attached to the oriented strandboard. The oriented strandboard was covered with a plastic vapor barrier for the wall assemblies and bituminous paper for the roof assemblies on which either the siding or the roofing materials were attached following the manufacturers’ installation instructions. The siding materials were a solid sheet of white color painted (the paint was latex based) 12.3 mm thick plywood siding and vinyl siding, with the vinyl sections installed horizontally according to the manufacturer’s instructions. The roofing materials were the U.S. common asphalt shingles and wood shakes installed according to the manufacturer’s instructions. The installations were designed to represent the common building construction in the United States. All the siding and roofing materials were purchased from a local building supplier. The specimens were conditioned at 50 ±10% humidity and 20 ±5 °C to constant weight.

Wetting Agent Application and Testing Procedure

The plant specimens and building materials were prepared and tested first without any wetting agents and then with each of the wetting agents considered, water, foam, and gel. The water wetting agent was from the municipal supply and sprayed using a garden hose sprayer. The time of water spray application was one minute, which was found sufficient to obtain the maximum retention of the water on the plants. The foam was “type A” foam applied using a portable self contained system specifically designed for foam application. The settings of the system were adjusted so that the quality of the foam typically used in the field was achieved. The foam was applied to the plants from two sides to obtain the foam coverage on the plants as uniform as possible. The gel used was from a single manufacturer. It was applied using a commercially available home use applicator provided by the manufacturer. The gel was applied at the quantity as high as possible and according to the manufacturer instructions. The application of the wetting agents was practiced to achieve the coverage as repeatable as possible before actual testing on the specimens occurred. However, some variability of the wetting agents on the plants was impossible to avoid again which mimics actual circumstances. The soil surface and the containers were protected with plastic foil before the wetting agents were applied, and the protection was removed before the plants were placed in the testing position. The application of the wetting agents on the building material specimens was similar as on the plants. However, the repeatability and uniformity of the application was better than for the plants.

Four different conditions were used on all the specimens which were to be investigated:

- Conditioned or dried without wetting agent application,

- Testing to be done within 10 minutes of the wetting agent application,

- In one hour after wetting agent application or at a shorter time if it was found in a test that most of the wetting agent had evaporated by that time,

- In one hour after wetting agent application while the specimens were exposed to a one kW/m2 irradiance and nine m/s wind, simulating high heat drought conditions. In some cases a shorter times of exposure were used if it was found in a test that most of the wetting agent had evaporated by that time.

For each condition and each specimen a Critical Flux for Fire Growth (CFFG) was determined using the bracketing procedure explained below. Typically, it was required to conduct three to five tests for each condition to determine the flux that supported fire growth on a specimen in about three minutes after the exposure. Two more replicate tests were subsequently conducted to confirm the results.

The test apparatus used to provide radiation exposure was the Intermediate Scale Calorimeter (ICAL)11. This apparatus provided a uniform and constant radiation heat flux onto a 1 m x 1 m vertical area in front of the radiant panel. The plant specimens were positioned on the weighing with the plastic container protected with a noncombustible board positioned between the plants and the radiant panel. The desired radiation heat flux exposures were achieved by adjusting the distance between the radiant panel and the specimens. The plants were positioned so that the desired radiation heat flux was on the plant branches closest to the radiant panel. A 300 mm high pilot flame from a 10 mm inner diameter copper tubing burner was used as the ignition source. The pilot flame size was chosen as a simulation of accumulated burning brands and ambers that sometimes arrive ahead of the wildfire flame front. In absence of any literature information on the size of the pilot flame, a size used was considered a conservative representation of possible urban wildland interface ignition sources. The pilot flame was relatively large, and typically ignited the plants around the flame in most tests. For the purpose of this project, the specimens were considered to have ignited when the fire growth in the form of flame spreading through the plants was observed (note that only the side of a plant closest to the radiant panel was exposed to the desired heat flux. The rest of plant received a lower heat flux due to a larger distance from the radiant panel, and because if was shielded from the heat flux by its own leaves and branches. The pilot flame was positioned just above the top edge of the plant container with the flame directed approximately into the front area of the plants.

The same pilot flame was applied to the building material specimens. The burner tubing end was located centrally about 50 mm above the bottom edge of the specimens, and with the closest part of the burner about 12 mm from the specimen surface. The flame was directed at about 45 ° angles toward the surface and was impinging on the surface. A typical experimental setup of a plant specimen is shown in Figure 1, and a typical setup of an external wall or roof assembly is shown in Figure 2.

All the tests were conducted by placing the specimens either on the weighing platform (plants) or into the standard ICAL sample holder (building materials). The ignition burner was lit for about five seconds before the shield that protects the specimens was removed exposing the specimen to a desired radiation heat flux. Observations were made of the time when the fire on the specimen started to grow. If the fire growth was observed before the expiration of three minute time (±30 s) of the start of the test the radiation heat flux was decreased and the test was repeated. If no fire growth occurred within three minutes, the test was repeated at a higher radiation heat flux. After the radiation heat flux was determined, which led to ignition at about three minutes, the tests at the determined flux were repeated at least two more times. If significant deviations from the radiation heat flux determined in the first test were found, the radiation heat flux was adjusted, and additional tests were conducted to determine the CFFG.

Figure 1 Experimental setup for plant test (Compacta Holly without wetting agent) Figure 2 Experimental setup for a wall assembly test (Vinyl siding with gel)

The three minute time was a conservative assumption of the time of the wildfire flame passage time. This was based on the work of Cohen12, who found that the exposure times from vegetation fires to be less than three minutes. Leonard13 describes the duration of fine fuel fires to be about one minute. These conditions do not apply to the exposure times from structural fires, which were not considered in this work.

In total, about 500 tests were conducted on 10 plants, two siding wall assemblies, and two roof assemblies. All the tests were photo documented as well and videotaped for later review.

Full-Scale Tests

Experimental Setup

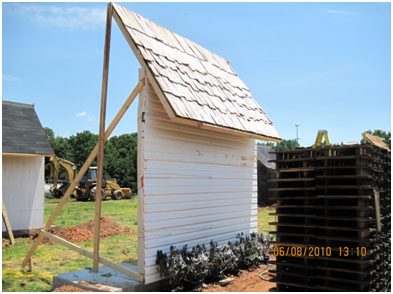

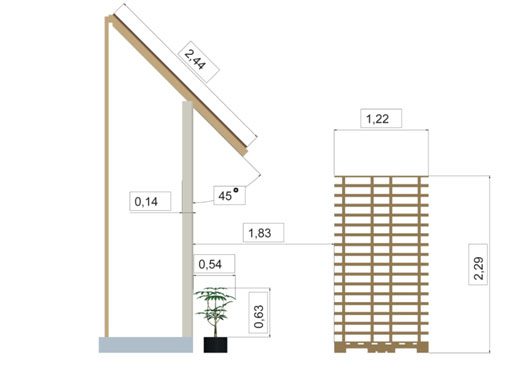

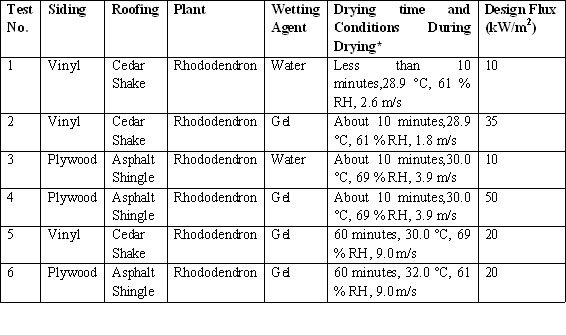

Based on the intermediate scale results, two wall/roof full-scale mockup assembly combinations were selected for six outdoor full-scale tests. Each of the mockups consisted of an external wall/roof combination. The first combination was plywood siding wall and asphalt shingle covered roof. The second combination was vinyl siding wall and cedar shake covered roof. The wall/roof angle was 45 degrees. Rhododendron plants were positioned in front of the mockup walls in all the tests. The wall assemblies were about 3.05 m high by 3.66 m wide, and were composed of wood studs the centers of which were 40.6 cm apart. The sheathing was 1.3 cm thick, oriented strandboard, and covered with “Tyvek” water barrier. Either standard vinyl siding (see Figure 5) or 13 mm thick plywood siding was installed as exposed surfaces following the standard construction methods. The roof assemblies were about 3.66 m wide and 2.44 m deep. They were constructed very similarly, except that the sheathing was 16 mm thick and the external surfaces were either standard asphalt shingles or cedar shakes. The mockup assemblies are shown in Figures. 3 – 5. The wetting agents, the drying times, conditions during the drying period, and the design exposure fluxes used for various tests are shown in Table 2. It should be noted that the exposure fluxes on most of the roof surface were expected to deviate from the wall flux exposures because of the geometry of the mockups.

The design exposure fluxes applied in each test were determined based on the intermediate scale test results1. The smaller CFFG of the two building assemblies for the particular wetting agent and drying condition was used for the full scale tests.

The exposure fluxes to the mockups were provided by burning stacks of weathered wood pallets. Although the pallets, their number, and arrangement were as similar as possible, differences in actual fluxes from the design were expected and measured as described in the Results section of this paper. The dimensions of the stacks, the dimensions of the mockups, and the test experimental setup are shown in Figures 3 – 5.

Table 2 Full-scale tests of two wall/roof combinations with various wetting agents

*Average ambient temperature, relative humidity (RH), and wind speed during the time of the wetting agent drying

Figure 3 Experimental setup of a full-scale test (vinyl siding and cedar shake roof mockup shown in the photograph)

Figure 4 Front view of the experimental setup showing the wood pallet stacks in the front and the wall/roof assembly in the back

Figure 5 Side view of the experimental setup

The external wall and roof assembly mockups were constructed by a local contractor who used the same manufacturer and types of products as used in the intermediate scale tests. About 0.91 m of the roof was extended beyond the wall. The assemblies were positioned on horizontal concrete slabs and braced as shown in Figure. 3. Six rhododendron plants in 26.5 liter pots were buried in front of the wall assemblies as shown in Figures 3-5 so that parts of the plants touched the walls. The plants had been conditioned to 20±5% of water content before the tests were conducted to simulate water-starved but still alive plants.

The wood pallet stacks were positioned in front of the mockup parallel to the wall. The distance between the wood pallet stacks and the mockup wall varied based on the desired flux exposure as shown in Table 2. The distances were determined based on the flux exposure calibration procedure described in the “Description of Tests” section below.

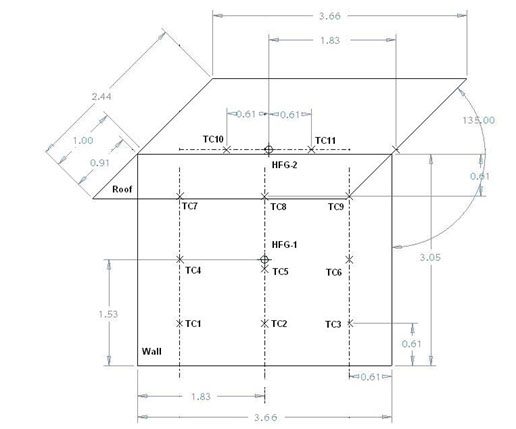

Instrumentation

Each mockup was instrumented with two 12 mm diameter water cooled Schmidt Boelter type heat flux gauges (HFG) of 100 kW/m2 range and 11 Type K, 0.51 mm thermocouples (TCs). The HFGs were positioned in the center of the wall, and in the vertical centerline of the roof about 1.0 m from the lower edge. The HFGs were installed in the holes pre-drilled in the assemblies so that the sensing surfaces were flush with the exposed wall siding surface and the roofing surface. Nine TCs were installed on the wall siding surface and two on the roofing surface so that the TC junctions were in contact with the surfaces. The locations of the HFGs and thermocouples on the wall are shown in Figure 5. The TCs were covered with the wetting agents prior to the tests. The HFGs were not covered with the wetting agents (the sensing surfaces were protected during the wetting agent application) except for Test 2. The HFG readings during this test reflect the fact that they were covered by the gel until it evaporated.

Figure 6 The locations of the TCs and the HFG on the wall

Description of Tests

Calibration of heat flux/distance relationship

The flux (mainly radiation heat) was provided by flames and hot surfaces from burning wood pallets arranged in three stacks. The wood pallet stacks and their arrangement are shown in Figures 5-7. A calibration test was conducted where two water cooled Schmidt Boelter type heat flux gauges of 100 kW/m2 range were positioned at 1.1 m height at 2 m and 4 m distances in front of the burning pallet stacks. The measured fluxes were recorded. The distances for the required wall heat flux exposures were calculated based on the two predetermined distances, the measured fluxes at those distances taking the changing radiation view factor into account, and assuming that the radiator (burning pallet stacks) surface temperature and emissivity were constant. The flux exposures followed a polynomial function of the distances. The distance for the 50 kW/m2 exposure was 0.8 m, the distance for the 35 kW/m2 exposure was 1.6 m, the distance for the 20 kW/m2 exposure was 2.2 m, and the distance for the 10 kW/m2 exposure was 3.5 m. The exposure fluxes on the roof were not calibrated and were expected to vary over the roof area.

Application and drying of wetting agents

Water was sprayed on the parts of the mockups using a garden hose spray nozzle for at least one minute. The gel was applied by using the garden hose applicator that was provided by the gel manufacturer. The gel manufacturer instructions were adhered to for the application. The gel was applied until the surfaces looked white (the gel was about 4 mm thick). Special care was taken when the gel was applied to the mockup edges and underneath the roof overhangs. Tests 1-4 were conducted within 10 minutes of applying the wetting agents. The drying conditions were the current weather conditions. Tests 5 and 6 were exposed to drying conditions for 60 minutes before the exposure to the flux from burning pallets. The drying conditions for these two tests were similar to those described as “severe drying conditions” for the intermediate scale tests. The wind velocity was provided by two large fans positioned so that the wind velocities over the wall parts of the mockups were as close as possible to 9 m/s, and as uniform as possible. The wind velocities were measured by a handheld rotating vane Anemometer. The heat fluxes from the sun during the drying periods were not measured. The ambient temperatures and relative humidity are given in Table 2 in the “Results” section of this paper.

Description of tests

For each test, the pallet stacks were placed in front of the mockup at a distance required for a desired flux exposure on the wall. This resulted in a somewhat higher exposure of the overhung part of the roof, and lower exposures of most of the roof beyond the wall. The flux received by the plants was probably close to the desired flux since the effects of lower view factors at the bottom of the walls were compensated by a shorter distance of parts of the plants to the burning pallet stacks.

Two ASTM E108 Type B brands were used as ignition sources in each test. One brand was positioned underneath the plant that was the closest to the middle of the bottom of a wall. The position of this brand was adjusted so that the flames from the burning brand would impinge directly onto some plant leaves and branches. The other brand was positioned with its center approximately 20 cm from the bottom edge on the vertical axis of the roof. The brands were sprayed with some diesel fuel and ignited shortly before the wood pallets were ignited.

The wood pallet stacks were also uniformly sprayed with diesel fuel to insure quick flame spread over the pallets, and as uniform burning of the pallet stacks as possible. About 15.2 kg of diesel fuel was used for each test. The pallets were ignited at several locations along the bottom of the stacks on the side facing the mockup. The ignition of the pallets was considered the start of each test.

REFERENCES

[10] Ettlinger, M.G., Beall, F.C., Development of a laboratory protocol for fire performance of landscape plants, International Journal of Wildland Fire, 13, p. 479-488, 2004.

[11] ASTM E 1623-07, “Test Method for Determination of Fire and Thermal Parameters of Materials, Products and Systems Using an Intermediate Scale Calorimeter (ICAL)”, 2007 Annual Book of ASTM Standards, Vol. 04.07.

[12] Cohen, J.D., Butler, B.W., Modeling Potential Structure Ignitions from Flame Radiation Exposure with Implications for Wildland/Urban Interface Fire Management, Proceedings of 13th Fire and Forest Meteorology Conference, Lorne, Australia 1996.

Results

Intermediate-Scale Tests

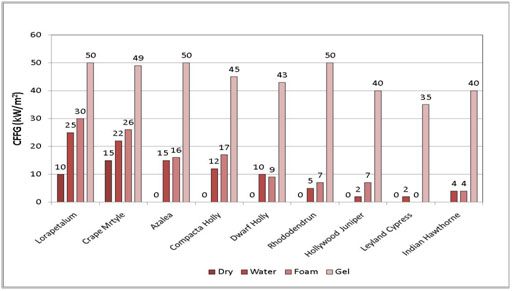

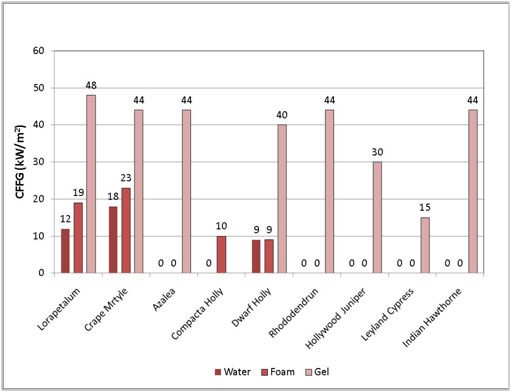

The CFFG determined for the plant specimens tested without a wetting agent and with wetting agent application without additional drying after the wetting agent application are shown in Figure 1. The CFFGs determined for the plant specimens tested with wetting agent application with additional drying after the wetting agent application (accelerated drying) are shown in Figure 3. Some drying times needed to be reduced. The actual drying times are given in Table 1.

The CFFGs determined for the plant specimens tested with wetting agent application and with the accelerated drying are shown in Figure 3. The drying times needed to be reduced from the originally planned exposure time of 60 minutes. The actual drying times are given in Table 2. The CFFG for Crape Myrtle could not be determined. Only the data with gel used as the wetting agent are available. The other wetting agents did not provide any additional protection of the plant under the accelerated drying conditions.

The CFFG determined for the external wall and roof assemblies tested without a wetting agent and with wetting agent application without additional drying after the wetting agent application are shown in Figure 6.

The CFFGs determined for the external wall and roof assemblies tested with wetting agent application with additional drying after the wetting agent application are shown in Figure 5. The drying times for the vinyl siding using water and foam as wetting agents needed to be reduced to 15 minutes.

Figure 1 CFFG for plants tested without additional drying after wetting agent application

Figure 2 CFFG for plants tested with additional drying after wetting agent application

Figure 3 CFFG for the plants exposed to the additional radiation heat flux of one kW/m2 and nine m/s wind

Figure 4 CFFG for external wall and roof assemblies tested without additional drying after wetting agent application (the dry value is not provided since the values are too scattered probably because the fire retardant on the material was not uniformly distributed)

The CFFG determined for the exterior wall and roof assemblies tested with wetting agent application and with the application of accelerated drying are shown in Figure 8. The drying times needed to be reduced from the originally planned exposure time of 60 minutes for the plywood siding wall assembly to 25 minutes. Only the data with gel used as the wetting agent are available. The other wetting agents did not provide any additional protection of the plant under the accelerated drying conditions.

It was observed during this project that some plants dried relatively non-uniformly. The areas of the plants that were drier than other areas were easier to ignite and burned with more intensity. To determine what the worst case situation might have been, we decided to test one plant that was completely dried beyond its 25 % water content condition. The plant that was selected was a Compacta Holly. Its water content was about 10 %. This plant was selected because of its relatively large size and dense leaves and branches. The results of the tests on this completely dry plant are compared in Figure 9 to the results obtained on the same plant at about 25 % of water content. The CFI determinations were not performed for the accelerated drying condition.

Figure 5 CFFG for the external wall and roof assemblies tested with additional drying after wetting agent application

Figure 6 CFFG for the external wall and roof assemblies exposed to the additional radiation heat flux of one kW/m2 and nine m/s wind

Figure 7 CFI comparison of Compacta Holly between its water contents of 20-30% and at 8-12% (completely dry)

Full-Scale Tests

The ignition times for individual parts of the mockups and for the plants for Tests 1-6 are shown in Table 3. The table also contains the general test information and the weather information at the starts of the tests. Figures 8-13 show the flux measurements at the two mockup locations, and Figure 14 shows an example of the surface temperature measurement results.

Table 3 Ignition times for various mockup components, pre-test drying times, and test weather conditions

Summary of the Results

1. All the wetting agent untreated plants except for Lora Pedlum and Crape Myrtle ignited without any external radiation heat flux. The wall and roof specimen require external radiation in order to ignite in three minutes.

2. The effectiveness of water and foam is similar and minimal if it is applied more than 10 minutes before the application of external heat flux.

3. The accelerated drying conditions cause both the plants and the building elements to ignite without any external radiant flux (what is called ignition is actually flame spread or fire growth, which require lower heat fluxes for the initiation of the process in comparison to the actual ignition, which is accomplished by a relatively large flame in this project), probably because the equilibrium moisture contained in the specimens after conditioning is removed to a large extent.

4. Gel appears to be the only wetting agent that protects the plants and building materials from ignition in wildland urban interface fire conditions if it is applied at least one hour prior to the arrival of the fire front. Some plants and building materials require the gel to be applied at shorter times prior to the fire front.

5. A significant number of variables that cannot be controlled, and are related to the plants as well as the wetting agent application, introduce a certain level of uncertainty in the level of the radiant flux that the plants and the building materials can withstand.

6. If the radiation exposures are known, the results of this work can be used to design the protection of plants and buildings from wildfires.

7. The duration of radiant heat exposure used in this work is conservative, which might improve the likelihood that the plants and building materials in actual fires would not ignite during fire front passage.

8. Future work is required to better understand the ignition properties of accumulated ambers and the times of fire front passage for various fuel categories, weather conditions, and landscape conditions.

- The full-scale test results confirmed the intermediate scale results indicating that the intermediate scale testing can be used to determine the three-minute CFFG for landscaping plants and external building materials.

- Firefighting gel is very effective in preventing fire growth in WUI fire conditions. This result was confirmed when radiation exposure fluxes of up to 50 kW/m2 are present for up to three minutes, and occasional direct flame impingement occurs.

- The conditions studied in this work are limited to wildland fire effects on buildings, and not building to building fire spread.

- The results of this work can be used to design the protection of buildings from wildland fire exposures when the exposures are known.

References

[1] Cohen, J.D., Preventing Disaster: Home Ignitability in Wildland-Urban Interface, Journal of Forestry, March 2000.

[2] Ettlinger, M.G., Beall, F.C., Development of a laboratory protocol for fire performance of landscape plants, International Journal of Wildland Fire, 13, p. 479-488, 2004.

[3] Cohen, J.D., Butler, B.W., Modeling Potential Structure Ignitions from Flame Radiation Exposure with Implications for Wildland/Urban Interface Fire Management, Proceedings of 13th Fire and Forest Meteorology Conference, Lorne, Australia 1996.

[4] Leonard, J. and Bowditch, P. 2003, Findings of studies of houses damaged by bushfire in Australia, presented to Third International Wildland Fire Conference, Sydney, Australia, 3–6 October.

RECOMMENDATIONS

This research has shown fire-blocking gel to be significantly more effective than either water spray or type A foam in preventing fire ignition or growth on buildings in many realistic wildland-urban interface (WUI) fire conditions. Results also showed that the level of protection of the gel depends on the amount/thickness and uniformity of it application. However, only one gel was tested, limiting the impact this information can have in protecting landscaping plants, structures, and those protecting them from fire. Further research is needed that will expand current results by investigating all major gel products on the market to gauge thickness and uniformity of application and the effects of these parameters on their effectiveness.

Significant uncertainty related to the effectiveness of gels and increase the safety of firefighters and homeowners in WUI fire environments needs to be reduced. The uncertainty mainly related to the landscaping vegetation size, plant type and configuration, as well as to the wetting agent, especially gel application thickness, uniformity, and type needs to be further investigated. In particular the research with the following objectives is suggested:

- Investigate gel application techniques and gel properties[1] of various gel manufacturers in relation to uniformity of substrate coverage and maximum quantity of gels that can be applied on building siding and roofing products.

- Using comparable application techniques, compare the effectiveness in terms of the critical flux for ignition/flame spread of currently commercially available gels for fire protection on building siding and roofing products as described in [1].

- Investigate the uniformity of gel concentrate and water ratios using various applicators and application techniques recommended by manufacturers and used by firefighters and homeowners.

- Investigate the effectiveness of various gels when pre-applied at times longer than one hour.

- Determine optimal ratios of the gel concentrate and water to provide optimal amounts of the gel applied onto various substrates.

- Investigate to what extent dried gel can re-absorb water using different water spraying techniques.

- Provide guidance to firefighters and homeowners as to which product to choose, and how to apply it for optimum protection from ignition.

- Provide guidance to gel manufacturers to improve the application techniques for their products.

REFERENCE

- Urbas, J. and P. Desai, Effectiveness of Pre-Applied Wetting Agents in Prevention of Wildland Urban Interface Fires, Proceedings of the 12th International Fire Science and Engineering Conference (Interflam 2010), July 2010 in Nottingham, UK, Interscience Communications Ltd., July 2010.

[1] Gel properties related to toxicity will not be investigated in this proposed project.

Recommendations

This research has shown fire-blocking gel to be significantly more effective than either water spray or type A foam in preventing fire ignition or growth on buildings in many realistic wildland-urban interface (WUI) fire conditions. Results also showed that the level of protection of the gel depends on the amount/thickness and uniformity of it application. However, only one gel was tested, limiting the impact this information can have in protecting landscaping plants, structures, and those protecting them from fire. Further research is needed that will expand current results by investigating all major gel products on the market to gauge thickness and uniformity of application and the effects of these parameters on their effectiveness.

Significant uncertainty related to the effectiveness of gels and increase the safety of firefighters and homeowners in WUI fire environments needs to be reduced. The uncertainty mainly related to the landscaping vegetation size, plant type and configuration, as well as to the wetting agent, especially gel application thickness, uniformity, and type needs to be further investigated. In particular the research with the following objectives is suggested:

- Investigate gel application techniques and gel properties[1] of various gel manufacturers in relation to uniformity of substrate coverage and maximum quantity of gels that can be applied on building siding and roofing products.

- Using comparable application techniques, compare the effectiveness in terms of the critical flux for ignition/flame spread of currently commercially available gels for fire protection on building siding and roofing products as described in [1].

- Investigate the uniformity of gel concentrate and water ratios using various applicators and application techniques recommended by manufacturers and used by firefighters and homeowners.

- Investigate the effectiveness of various gels when pre-applied at times longer than one hour.

- Determine optimal ratios of the gel concentrate and water to provide optimal amounts of the gel applied onto various substrates.

- Investigate to what extent dried gel can re-absorb water using different water spraying techniques.

- Provide guidance to firefighters and homeowners as to which product to choose, and how to apply it for optimum protection from ignition.

- Provide guidance to gel manufacturers to improve the application techniques for their products.

REFERENCE

- Urbas, J. and P. Desai, Effectiveness of Pre-Applied Wetting Agents in Prevention of Wildland Urban Interface Fires, Proceedings of the 12th International Fire Science and Engineering Conference (Interflam 2010), July 2010 in Nottingham, UK, Interscience Communications Ltd., July 2010.

[1] Gel properties related to toxicity will not be investigated in this proposed project.

Best Practices

Wetting agents have the best chance of protecting structures in WUI fires if used in conjunction with traditional preventive measures including defensible space, the use of difficult to ignite building materials and other “firewise” measures.

Gels are the most effective when pre-applied at a time shorter than one hour prior to the arrival of the fire front. Therefore, homeowners who wish to protect their property, and then evacuate, should use gels exclusively. Firefighters when wearing protective gear, and are not expected to be exposed to high radiation exposures, might be able to successfully use water and foam if applied just before the fire front arrival. CAUTION: since the exposures required to ignite pre-wetted plants and structures are higher than what their protection is designed for, firefighters might get trapped by WUI fires, and should avoid attempting saving houses when uncertain about the exposures.

The effectiveness of gel pre-applied at times longer than one hour prior to the fire front arrival has not been studied. Also, only one type of gel was investigated in this project. However, the experiments indicated that gel applied to plants tend to dry faster than in one hour in dry and windy conditions. That can lead to reduced protection from ignition.

Plants with leaves similar to Hollywood juniper and Leyland cypress cannot be protected from ignition with gels or other wetting agents because the gel cannot penetrate the thick outer layer of the leaves. The inside of the plants thus remains unprotected, and typically ignite immediately if exposed to a small flame.

If mixed landscaping vegetation is used, it is likely that the plants that ignite at relatively low radiation exposures can produce relatively large flames that might ignite other plants, which in turn can ignite structures .

Completely dry plants cannot be protected with gels as effectively as relatively dry but still alive plants.

The full-scale tests demonstrated that the gel can protect structures from ignition and fire growth when exposed to direct flames for short periods of times (up to 10 seconds).

No pre-applied wetting agents can protect structures from long duration exposures caused by nearby burning structures.

The exposures from wildland fires cannot be quantified at this time. As guidance, Cohen’s experimental results and SIAM model calculations [1] can be used to estimate exposures. The further away from a structure the wildland vegetation ends, the lower the exposures will be. In addition the thinned vegetation, and lower height vegetation will produce lower radiation exposures on the landscaping plants and structures.. Cohen found in [1, 2] that the flame size 20 m (height) x 50 m (width), will produce the radiant heat flux of about 46 kW/m2 when about 10 m from a structure. Higher distances and lower flames will produce lower exposures. Also, flames from scattered or thinned trees or bushes will produce lower fluxes than flames from thick forest or densely grown bushes.

It is likely that any pre-wetting will be ineffective in protecting structures located very close to a forest or tall and dense bushes (less than 10 m) where a possibility exists for very high radiation exposures and direct flame impingement on structures.

Gels should be applied uniformly and at a highest possible thickness that does not cause flowing. Attention should be paid to edges and cavities.

Any other combustibles around structures (trash, wood piles, fences, etc.) must also be protected by gel to avoid large ignition sources that can be ignited by ambers or flying brands.

The gel applied should have sufficient viscosity to produce a layer of at least a few mm thick. Necessary adjustments must be made, on the spraying equipment to achieve this, if necessary. Practicing is recommended before a fire.

An ASTM standard test method is being developed, which (if successfully developed) will allow testing of other wetting agent/plant/building material combinations in the future.

REFERENCES

[1] Jack D. Cohen. 1995. Structure Ignition Assessment Model (SIAM). General Technical Report PSW-158. Albany, CA: USDA Forest Service, Pacific Southwest Research Station: 85-92.