Gathering real-world data — and experience

When applying to colleges, Jabrail McBride set his sights on NC State and UNC Charlotte. It was only after touring several engineering schools that Jabrail McBride realized UNC Charlotte was the best fit for him.

“In particular, I found Charlotte’s senior design concept to be much stronger than what the other schools offered,” said McBride, who knew that to earn a bachelor’s degree in engineering, students must complete a capstone course, otherwise known as the “senior design project.” Prospective engineers are often aware of this milestone, but even as an entering first-year student, McBride was already eager to tackle the capstone.

Before McBride began his senior design project, though, he took advantage of real-world experiences, first as a supply chain engineer intern with Krispy Kreme, where he worked directly with a software engineer to implement a new inventory system.

Next, he worked as an energy and sustainability engineer in the year-long co-op program of Highwoods Properties. In this role, McBride learned firsthand about contributing to sustainability through energy cost savings. The Niner Engineer helped build interval data that quantifies energy cost savings, presented energy performance reports to management and worked with Energy Star certifications to better appreciate the energy and sustainability field.

In his senior year, McBride delved into the engineering capstone.

“The senior design process has become one of my most cherished experiences during my time here,” said McBride. “My fellow aspiring engineers and I were entrusted by our industry partner, Atrium Health, with an important orthopedic issue: repeated shoulder dislocations. Our goal was to gather valuable data on surgical techniques to reduce recurrent shoulder dislocations.”

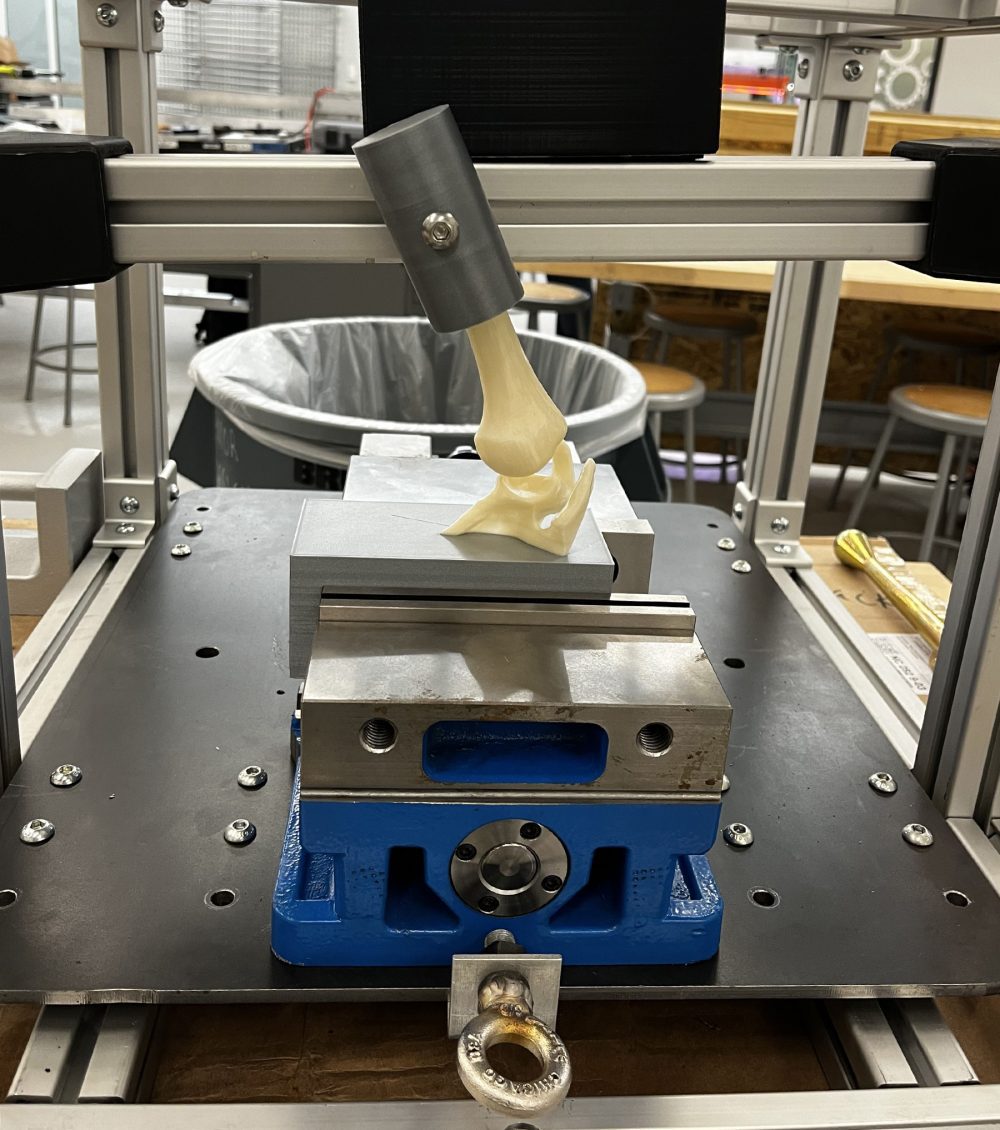

McBride and his team designed and developed a machine that simulates, tests and measures how much force it takes to dislocate a human shoulder. “It uses sensors, weights, and other equipment to essentially ‘pull’ on a cadaver shoulder to simulate injury conditions,” explained McBride.

“We applied the knowledge gained in class to develop a real-world solution to a pressing issue,” explained McBride. The data, and the machine the team built to capture it, will ultimately help reduce repeated shoulder dislocations. In the future, their testing methods could be applied to study other joints and injuries, contributing to broader knowledge of orthopedic biomechanics.

His practical experiences solidified McBride’s decision to pursue a career in engineering where he can identify challenges and contribute to solutions. The internships and senior design project were “immensely challenging and rigorous, but the journey is truly worthwhile,” said McBride. “They definitely influenced my career direction.”

As he graduates, McBride has secured a full-time associate sales engineer position with Johnson Controls where he will help built environments be healthier and more sustainable.