Expanding 1998-2015

When Bob Snyder stepped down as dean of The William States Lee College of Engineering in 1998, the university passed the engineering leadership baton to another “Bob,” when it named Robert (Bob) Johnson as interim dean in 1999 and then permanent dean in January 2000. The two deans shared the same first name and an unlikely connection in people’s minds to cartoon characters. Snyder’s name conjured images of Looney Tunes, because of the Bugs Bunny and Daffy Duck ties he wore. Johnson was sometimes referred to jokingly and admiringly to as “Bob the Builder,” because of his role in leading the construction efforts of four new engineering buildings. It was Johnson’s vision and determination that added 500,000 square feet to the college of engineering during his tenure as dean. The buildings were essential to the establishment of new programs and growth of existing programs during a time when enrollment increased almost 50 percent, from 2,156 in fall 2000, to 3,093 in spring 2015.

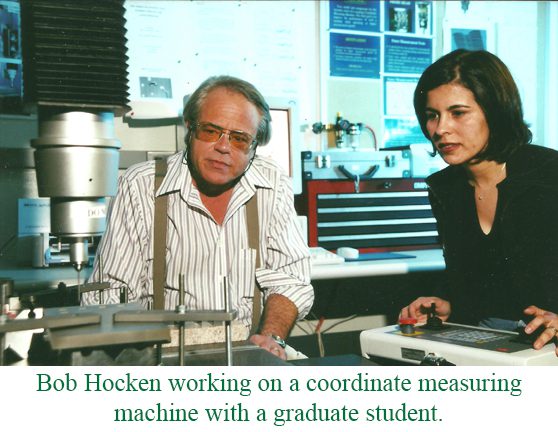

Johnson’s first exposure to UNC Charlotte and the Charlotte community was in 1992, when Bob Hocken invited him to a National Science Foundation conference here. The conference was held at the University Hilton across the street from the UNC Charlotte campus.

“I didn’t even know where Charlotte was,” Johnson said. “Actually, I thought I was going to Charleston. But I recognized right away that this City of Charlotte was on the move and something was going to happen here. I was convinced it was beginning to happen already. When a job opened up a couple years later I decided to take a look.”

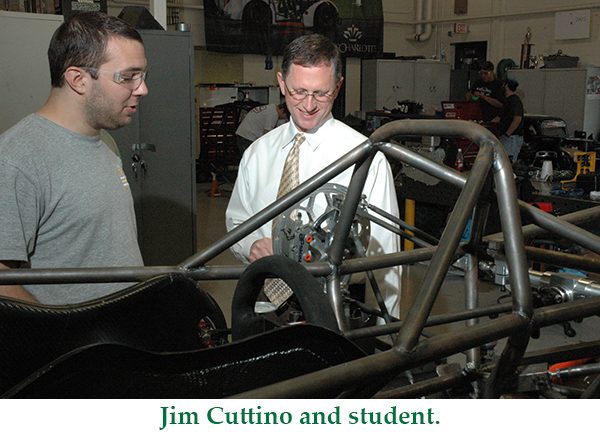

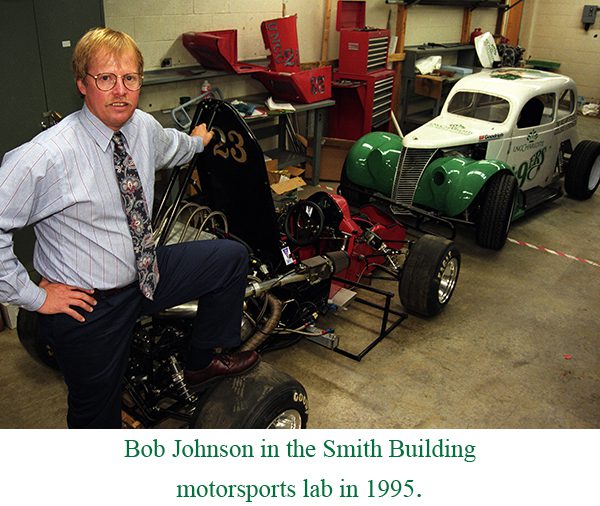

UNC Charlotte hired Johnson in 1994 as chair of the Mechanical Engineering Department. He had previously been in the same role as mechanical engineering professor and chair at the University of Illinois at Urbana-Champaign. The new mechanical engineering Ph.D. program was just beginning at UNC Charlotte, and the university was looking to Johnson and his experience at one of the country’s largest research institutions to build the program. There was a long way to go, though, with only 14 faculty members in mechanical engineering when he started.

“I can vividly remember walking up the hill to Smith Building on my first day and questioning my decision,” Johnson said. “I was wondering what I had got myself into at this little place.”

As chair of Mechanical Engineering, Johnson was successful in gradually building the department’s graduate programs. A number of students were being attracted to the precision engineering and metrology program, which was off to a good start and was growing in the strong manufacturing economy of the time.

“The graduate programs grew slowly,” Johnson said. “The heart of the programs to start was manufacturing metrology. They had funding, they had students and they had good support. We started to branch out slowly into fluid mechanics, materials and design.”

Johnson saw the importance of healthcare related programs to the community of Charlotte, and began hiring faculty in the interdisciplinary field of biomedical engineering. They would partner with faculty from biology and other disciplines in the Cameron Center to build the core of the university’s program in biomedical research.

Once he was in Charlotte, Johnson quickly realized that a large economic engine here, and the reason a number of his students were here, was auto racing. To capitalize on this huge industry, he started the automotive and motorsports program with classes and research at the undergraduate and graduate levels.

Five years into his career at UNC Charlotte, Johnson got the opportunity to throw his hat in the ring for the position of dean of the college of engineering.

“As chair at Illinois, I realized I like doing this sort of thing, and thought I was pretty good at it,” Johnson said. “When the opportunity opened up here for the position of dean, I was ready to do something a little different and thought could make more of a contribution doing it. I thought I would do it for about five to seven years, and here I am 20 years later.”

Biomedical Engineering

Even before he became dean, Johnson was active in building the biomedical engineering research program at the university. “The very first person I hired at UNC Charlotte was Robin Coger in bioengineering,” Johnson said. “It seemed clear biomedical research was something we should be in.”

Other hires followed in the succeeding years, creating to a talented team of researchers who built productive research and academic programs.

Coger came to UNC Charlotte in 1996. She had recently completed her Ph.D. at the University of California Berkeley and a post-doctoral program at Harvard Medical School. Her research specialty was tissue engineering and the storage of cells, tissues and organs at low temperatures.

“I came during the time when a number of people were being hired for research at UNC Charlotte,” Coger said. “They wanted us to build on the excellent research being done at the time, with the goal of reaching a higher Carnegie designation.”

The team of interdisciplinary biomedical researchers got its start in the C.C. Cameron Applied Research Center. “The Cameron Center was critical,” Coger said. “It was a wonderful, fruitful environment. In terms of accessibility, it’s a little easier to find out what people are doing when you run into them in the hallways. It made it easier to think about collaborations in different ways.”

Charles Lee came to the group in 1999, also from UC Berkeley. He too credits the Cameron Center with the group’s success.

“Cameron was an almost ideal place to incubate these collaborations,” Lee said, “because we were all in Cameron with our labs and equipment. Our goal was having like-minded researchers with common interests and common projects working together in close proximity.”

In 2001, the group succeeded in securing National Institutes of Health funding to establish the

collaborative Bioengineering Research Partnership (BRP). The partnership was comprised of three research areas, one that looked at oxygen transport inside of tissue-engineering products, another in the micro-patterning to combine different cell types, and a third involving machine perfusion to lengthen the time donated organs can be preserved.

Out of BRP grew the Center for Biomedical Engineering Systems (CBES), which was established in 2006. With 42 affiliated researchers, CBES research focus areas were molecular engineering and design, medical therapies and technologies, and biomechanics and mobility research.

On the academic side, all biomedical engineering studies at UNC Charlotte were initially at the master’s and Ph.D. levels. In 2015, the Mechanical Engineering Department began offering an undergraduate concentration in biomedical engineering.

(For more information see the section “The Centers” and the chapter “Biomedical Engineering.”)

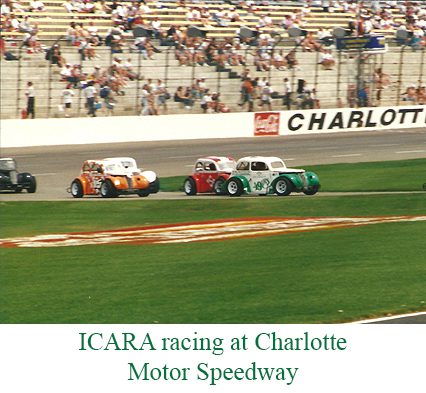

Motorsports Engineering

The Charlotte, North Carolina region was the home of NASCAR and when it came to motorsports engineering, The William States Lee College of Engineering was in the right place at the right time. NASCAR was booming in the early 2000s with numerous teams within a 20-mile radius of the UNC Charlotte campus. The teams were becoming more advanced in their research and development to optimize performance, and they were hiring engineers. Aspiring race engineers from throughout the country knew this, and they were moving to Charlotte for their education.

“I met a lot of students who were from out of state and I was shocked that they had come so far to go to school,” Johnson said. “When I asked them why they were here, they all said the same thing, ‘I want to get into racing as an engineer or a crew chief.’ We weren’t really doing anything for these kids at the time and I started debating the options, figuring out what we could do. I sat down with Jerre Hill, who was the other key person interested in this, and we crafted a concentration area.”

UNC Charlotte approved the motorsports engineering concentration in 1997, although a number of faculty across campus were skeptical. “I don’t think they appreciated that racing had come a long way and was not just a redneck sport with shade-tree mechanics,” Johnson said. “Faculty governance did approve the concentration, though. It was the first concentration in engineering and I think the first concentration on campus.”

The motorsports engineering concentration was part of the Bachelor of Science in Mechanical Engineering program. Students interested in the concentration could apply for admission during their sophomore year. When admitted to the program, they began taking automotive-related courses as their technical electives. They also had to participate on motorsport engineering teams such as Formula SAE and Mini-Baja.

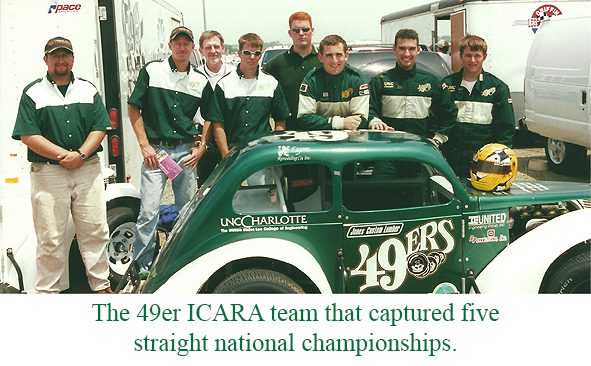

In the early days of the program, students also had the opportunity to participate in wheel-to-wheel racing against other colleges of engineering. The brainchild of Charlotte Motor Speedway President Humpy Wheeler, the Intercollegiate Auto Racing Association (ICARA) pitted seven schools against each other in a season-long series of Legends car races at tracks throughout the southeast.

The UNC Charlotte ICARA team benefited from having many talented racers who grew up driving and working on go-cart and other junior-level race cars. The 49ers captured five straight ICARA national championships. An economic downturn in 2001 made it difficult for a number of the schools to continue fielding teams, though, and in 2002 ICARA ended.

“It was an expensive activity,” Johnson said. “We had lots of interest because of where we were located. It was educational in terms of being a team-building activity that taught car performance and such. The student learned a lot about those cars when set them up for different tracks, and put them back together when they got wrecked.”

In terms of facilities, the motorsports engineering program benefitted greatly from university capital projects. In 2005, the 10,000-square-foot Motorsports Engineering Laboratory (later to be named the Kulwicki Laboratory) opened adjacent to the new Duke Centennial Hall. The new lab gave motorsports teams the room they needed to work on their projects. In 2012, the 16,500-square-foot Motorsports Research Building opened as the new home of research and graduate-level education in the areas of automotive and motorsports engineering.

Through their studies and hands-on projects, the motorsports engineering students were getting the education they needed to be successful. They were also benefitting from the increasing complexity of auto racing.

“There was a big change in NASCAR culture,” said Mesbah Uddin, director of the motorsports engineering program. “We were seeing more and more engineers being hired by teams, which was a very good thing for our program. What the employers appreciated about our programs was the very hands-on nature of the degree.”

The economic downturn in 2008 did impact a number of race teams, who had to cut positions to save money. The skill sets required from engineers also shifted, as teams looked for people with more analytical abilities who could do simulation testing instead of more expensive full-scale testing.

“More teams were looking to us for students with strong analytical skills,” Uddin said. “Race teams began relying hugely on vehicle simulations and aerodynamics simulations. So, we started offering more courses and senior design projects that had analytical skills components.”

Environmental Engineering

Always an important concern in engineering work, environmental impacts were becoming more and more critical at the end of the 20th century and beginning of the 21st century. Engineers were beginning to explore the interrelationships between the built and natural environments, and to consider long-term impacts and sustainability. To provide important research on these issues in the Charlotte region, UNC Charlotte started its first interdisciplinary environmental research program in 2001.

The program began in the Cameron Center. UNC Charlotte departments involved included Civil Engineering, Engineering Technology, Electrical and Computer Engineering, Geography and Earth Science, Architecture, Biology, Economics and Community Relations. Initial research focus areas included disaster response and mitigation, water and air quality, compliance issues, waste disposal and landfills.

The first director of the program was Dr. Hilary Inyang, who came to UNC Charlotte from the University of Massachusetts-Lowell, where he was the founding director of the Center for Environmental Engineering, Science and Technology. UNC Charlotte hired Inyang as the first Duke Energy Distinguished Professor of Environmental Engineering and Science, a joint position shared between Environmental Engineering and Geography and Earth Science.

With strong backing from Duke Energy, Inyang made energy-related environmental issues a priority of the new program, which took the name Global Institute for Energy and Environmental Systems (GIEES). Two new Civil Engineering faculty members, Vincent Ugunro and John Daniels, had come from the University of Massachusetts-Lowell with Inyang to work with GIEES.

“I came here for chance to be part of the new research group,” Daniels said. “UNC Charlotte was committed to growing excellence in geo-environmental engineering, which was the interface of geotechnical engineering and environmental engineering. It included things like groundwater contamination, remediation, landfills and industrial by-products such as fly ash. That’s what attracted me here, the chance to be part of such a team.”

With a number of international relationships, GIEES succeeded in sharing environmental research and learning throughout the world through post-doctoral exchange programs and international conferences. The economic downturn in 2008 limited the travel resources of many universities, though, and environmental leaders at UNC Charlotte decided to change the program’s emphasis to a more regional focus. Inyang soon after got the opportunity to become vice chancellor and distinguished professor at the Botswana International University of Science and Technology, and left UNC Charlotte.

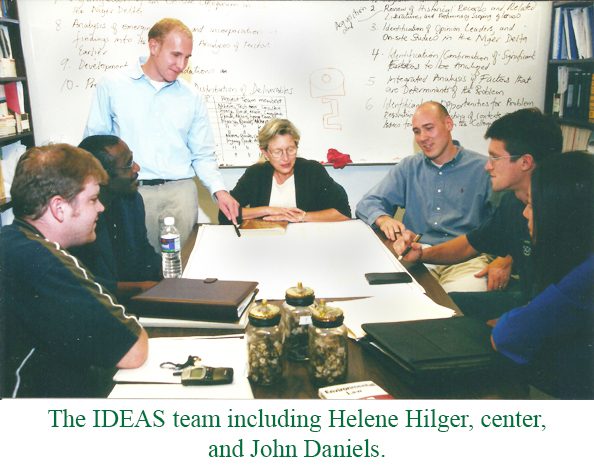

In 2010, GIEES was renamed as the Infrastructure, Design, Environment and Sustainability (IDEAS) center. IDEAS researchers concentrated their efforts on sustainability areas including environmental characterization and monitoring systems, sustainable energy infrastructure, private and public sector issues related to urban growth, environmental modeling, containment source control, physico-chemical interactions and durability of materials. The new director of IDEAS was Civil Engineering faculty member Helene Hilger.

“UNC Charlotte established IDEAS to bring university research expertise to the solving of problems that arise from the complex relationships between humans and their environment,” Hilger said. “IDEAS purpose was to provide a venue for the university to use its expertise to respond to environmental and sustainability challenges and contribute viable solutions.”

IDEAS researchers built strong ties with city and county municipal governments, as well as regional industrial partners.

“We provided regional leadership to accelerate a cultural and technological shift to more sustainable practices,” Hilger said. “We fostered dynamic and strategic research collaborations among multiple university disciplines, promoted a region-wide climate of cooperation, and offered students a knowledge base and experience that allowed them to contribute to these advances.”

To serve smaller municipalities in their sustainability initiatives, IDEAS created the Environmental Assistance Office. As an interdisciplinary group of students and faculty, EAO worked with government agencies and small businesses to increase effective pollution prevention practices.

IDEAS also had strong ties to the university’s doctoral program in Infrastructure and Environmental Systems, providing students with real-world research projects. “The environmental message we wanted to give these students is all stuff comes from the earth and from natural systems,” Hilger said. “The earth provides lots of free services such as air filtration, water filtration, bees that pollinate and lots of other things you don’t notice. When you mess with these natural services you mess things up and you lose it. And getting it back doesn’t come cheap.”

Hilger retired from UNC Charlotte in 2012, and Srinivas Pulugurtha took over as director of IDEAS. Pulugurtha added a number of transportation related research areas to IDEAS list of infrastructure and environmental services. Bringing expertise to topics such as concrete performance, improved materials, excavation methods and benefit cost modeling, IDEAS researchers won numerous projects from the North Carolina Department of Transportation.

Another area where IDEAS and Civil Engineering researchers began to take a regional and national leadership role was in coal fly ash. Electric utilities had experienced a number of failures in their traditional methods of storing coal ash, and UNC Charlotte researchers brought to bear their expertise in the containment, stabilization and re-use of the waste material. With more faculty researchers involved in coal fly ash than any other engineering department in the country, Civil Engineering also took the leadership role in a number of public and private coal ash oversite and policy committees.

(For more information, see “The Centers” section and the “IDEAS” chapter.)

Precision Engineering and Metrology

Since its founding in the 1980s, the precision engineering and metrology program had enjoyed success in recruiting faculty, building graduate programs and winning research grants. With state-of-the-art facilities in the Cameron Center, the program was one of the finest and most-respected precision engineering groups in the world.

Through Director Bob Hocken’s connections from working at the National Bureau of Standards, later the National Institute of Standards and Technology (NIST), the program was able to establish immediate collaborations with a number of industry partners. When the NSF named the program an Industry/University Collaborative Research Center in 1995, the resulting grant money helped establish a number of faculty and graduate research projects.

One of Bob Hocken’s first initiatives was to build an affiliates program of industry partners. For the price of $30,000 a year, affiliates had access to the resources of the program They were able to work with students and faculty on projects for their companies, the which resulted in cutting-edge solutions to manufacturing challenges and the opportunity to hire some of the best students into their organizations.

The many successes of the precision group led to the physical growth of the program, which was quickly outgrowing its allotted space in the Cameron Center. In 2000, builders completed a 28,000-foot expansion to Cameron, providing much-needed space for all of the building’s programs, including precision engineering and metrology.

Some of the research areas and projects the group conducted included precision machine design, vector sensors for coordinate measuring machines, surface texture measurement instruments, high-precision optics, modeling of virtual manufacturing systems and giant magneto-resistive sensors. A new and growing area for the group in the early 2000s was high-speed machining techniques.

As a recognized leader in the world of precision measurement, faculty members from the UNC Charlotte precision group served on a number of committees of the International Organization for Standardization (ISO).

The facilities for the precision group got a huge boost in 2005 with the opening of Duke Centennial Hall. Duke Hall became the new home of Mechanical Engineering and included dedicated new laboratory space for precision engineering and metrology. The group moved in with 300 tons of equipment.

As the home of Mechanical Engineering, Duke Hall contained classrooms and machine shops to support the undergraduate program. The shops were also of great importance to precision research.

“Duke Centennial Hall provided not only state-of-the-art laboratories for our work,” Hocken said, “but also gave us the capabilities to make our own parts and build all the things we wanted. This was important to our research, and to the expansion of our hands-on engineering programs.”

The new precision engineering and metrology center included a suite of six laboratory modules, all with highly precise vibration and temperature control. “We couldn’t have ultra-precision machine capabilities if we didn’t have this level of control,” Hocken said.

At this same time, economic forces were creating an evolution in the type of research projects the group worked on. “We had to go where the money was,” Hocken said, “and what our affiliates wanted was more short-term practical things.”

NSF funded projects were also changing, becoming more collaborative with numerous teams working on separate smaller parts that came together into an overall whole. This led to UNC Charlotte researchers working with schools including MIT, UC-Berkeley, UCLA, Stanford and others on projects such as the Sub-Atomic Measuring Machine and plasmonic lithography.

(For more information see “The Centers” section and the chapter “Center for Precision Metrology.”)

New Buildings

The origin of six new buildings on the north side of the UNC Charlotte campus started in 2001 with a report written by Bob Hocken. Based on the centennial campus concept at N.C. State, which designated part of the campus as an area in which on-site private industry representatives could collaborate with university faculty and students, Hocken’s report proposed that UNC Charlotte create a similar subset of its campus. The UNC General Administration expanded Hocken’s proposal to include such cooperative research zones on all UNC campuses, and passed the resulting Millennial Campus Act. UNC Charlotte immediately began planning new buildings that would be included under the terms and conditions of the act.

“(Chancellor) Jim Woodward decided the new building should be over here,” Johnson said, “and that they should be engineering, science and STEM focused buildings. Mechanical Engineering was the leader for us in industry partnerships, so we decided it would get our first building that would be part of the new campus.”

UNC Charlotte designated 100 acres of its campus as the area that would encompass Millennial Act facilities. Stretching from Highway 29 on the north side of the UNC Charlotte campus to the Cameron Center and Smith Building, the area became known as the Charlotte Research Institute (CRI).

Earth movers began site work on the CRI campus in 2002. The first buildings on the site would be for Mechanical Engineering, Motorsports and Physics. Johnson was integrally involved in the team that would design the engineering building, which was initially called the Engineering Research Building and later renamed Duke Centennial Hall.

“We had a good design team,” Johnson said. “We gave the building a traditional academic look, which was the kind of thing parents and industry people wanted to see. At the dedication of the building, Paul Anderson of Duke Energy looked around and said ‘Yeah, this looks serious.’ I realized at that moment we got it right. The building has become an icon for the college and for the campus.”

Within Duke Hall’s exterior of the red brick and columns, the design team created an interior that facilitated the hands-on learning philosophy of the college. The 107,000-square-feet of space included classrooms, lecture halls, research laboratories, machine shops, project space, offices, study areas, computer labs, and computational and modeling facilities. All of these elements combined to provide the infrastructure needed for the college’s undergraduate design sequence, and graduate and faculty research.

The building opened in 2005 as the home of Mechanical Engineering, the Center for Precision Metrology and the Dean’s Office. On September 8, 2006, the university officially named the building Duke Centennial Hall in recognition of the long-standing relationship between Duke Energy, which celebrated its 100 birthday that year, and UNC Charlotte.

Adjacent to Duke Hall was a new 10,000-square-foot facility for the motorsports program. “When Duke Hall was being designed, the motorsports program was already pretty successful,” Johnson said. “So, we made the case to build a separate motorsports lab to give it some proper space. We wanted to keep motorsports away from metrology for vibration reasons and away from the other classrooms and offices for noise reasons. So, we got that separated building, which was really valuable space. It took the program to another level.”

The motorsports lab provided space for the various student teams such as Formula SAE, Baja, Legends and senior design. It also housed engine and chassis dynamometers, and a student study space. On October 13, 2010, five years after its opening, family of late NASCAR driver Alan Kulwicki joined UNC Charlotte officials to dedicate the building as the Alan Kulwicki Motorsports Laboratory. The first college graduate engineer to win the NASCAR season championship, Kulwicki was a strong supporter of education. In his honor, the Kulwicki family made a contribution to fund equipment for the lab and student scholarships.

On the same day the university dedicated Duke Hall, it also dedicated the Charlotte Research Institute’s second building, naming it William Grigg Hall. Originally called the Optical Science and Physics Building, Grigg Hall’s namesake was chairman emeritus Bill Grigg of Duke Energy, who served the company for 35 years prior to his retirement in 1997. The new home of the Physics Department and the Center for Optoelectronics and Optical Communications, Grigg Hall also housed electrical engineering researchers involved with the optics center.

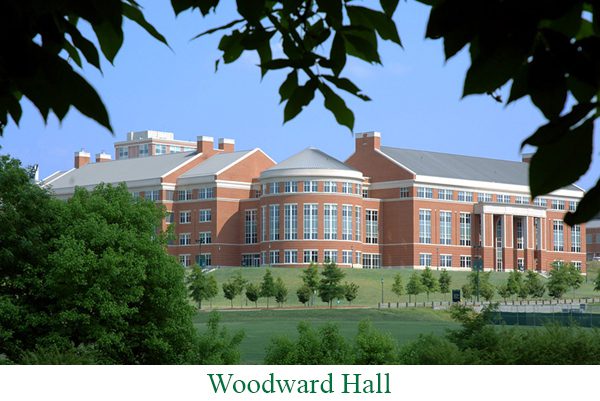

Another new STEM related building that opened on the CRI Campus in 2005 was the Science and Technology Building, which would later be named Woodward Hall. The 225,000-square-foot building was the new home of the Electrical and Computer Engineering Department, who shared the facility with the College of Information Technology and the Department of Biology.

ECE occupied the second floor of the west wing of Woodward Hall. The new space included six state-of-the-art classrooms, a 280-seat lecture hall, a distance learning classroom, computer labs, offices and new undergraduate instructional and research laboratories with modern equipment and work benches.

Researchers from the Lee College of Engineering’s biomedical engineering research group also shared laboratory and office space with their collaborators in the Biology Department on the fourth floor of the north wing.

In January 2012, the Lee College of Engineering added the Motorsports Research building to its facilities on the north side of campus. The building was adjacent to the Kulwicki Motorsports Laboratory and Duke Hall.

“For Motorsports Research we made a budget proposal to the Provost, which eventually went to the Chancellor,” Johnson said. “We made a case that with the number of students in the program, which was about 100 at the time, we needed more space, equipment and faculty. The Chancellor allocated money for faculty over a three to five year period, and we were able to make a couple hires. Then in 2008, the economy tanked and we never got all the money. But we did get the new building.”

Mesbah Uddin was one of the new hires, and went on to become director of the Motorsports Engineering program.

“We really needed the new building, because we had no space for graduated research work at all,” Uddin said. “Motorsports Research made it possible for our graduate program, which was up to 20 students, to grow.”

The 16,500-square-foot $4.5 million building became the new home of research equipment including a water tunnel, wind tunnel, alternative propulsion dynamometer test cell, computational labs and other research facilities, as well as offices and study areas for graduate students and faculty.

“One major assets of new building was whenever we gave tours to prospective students, it was very rare that they didn’t want to come here,” Uddin said. “We had students from all across the country including New York, Florida, New Jersey, Pennsylvania and more. When we gave them a tour they would tell me, ‘I’m coming here.’”

With the opening of Duke Centennial Hall, the Kulwicki Motorsports Lab, Grigg Hall, Woodward Hall and Motorsports Research, the entire center of gravity of the UNC Charlotte campus was shifting northwest towards the Charlotte Research Institute. This change in the balance of campus was increased even more in 2012, with the opening of UNC Charlotte’s largest academic building to date, the Energy Production and Infrastructure Center.

Since the early 2000s, the Charlotte region was becoming home to more and more energy companies such as AREVA, Shaw Group, URS, Siemens, Westinghouse, ABB and others. There were also traditional energy companies such as Duke Energy, Piedmont Natural Gas, SCE&G, EPRI, municipal co-ops and more. All of these companies had one thing in common, a growing need for more energy engineers.

Dhiaa Jamil, a Lee College of Engineering alumnus and Duke Energy’s group executive and chief nuclear officer, and Mark Boomgarden, senior vice president of operations at Akoustis, were both on the college of engineering advisory board at the time. Together, they met with Johnson to discuss a not-to-distant workforce crisis in energy engineering. Johnson researched the topic more extensively, and concluded the problem might be even bigger than the companies around Charlotte realized. The entire country faced a national energy crisis, and the area of renewable energy technologies was booming. These issues added significantly to the need for more energy professionals and energy research.

Johnson wrote a white paper in 2007 that envisioned a campus-wide energy initiative that encompassed numerous UNC Charlotte departments and colleges. The other disciplines were not interested in the project, though, so he decided to pursue an engineering-only strategy.

“I revamped the white paper (the white paper is here) to make it just engineering,” Johnson said. “(Chancellor) Dubois had just come here about nine months before, and he wasn’t that interested in the proposal to start. I kept talking it up for about year, but it still got no traction.”

Help arrived from the professional energy industry in the person of Tom Christopher of AREVA. Based in Virginia, Christopher had close ties with the Lee College of Engineering and was willing to take on the challenge of convincing UNC Charlotte to develop programs and facilities to address the energy workforce crisis.

“Tom was a very articulate guy,” Johnson said. “I told him, ‘I really needed your help on this. No one is listening to me. Will you come down and meet with the Chancellor and the Provost?’ He said, ‘Absolutely.’”

Johnson tried for several months to set up the meeting, but couldn’t generate a lot of enthusiasm on the UNC Charlotte side. He kept trying, and eventually a short breakfast meeting was arranged.

“I had confirmation from Christopher’s office the night before the meeting that he was ‘wheels up’ and would be in Charlotte tonight and at the meeting on campus in the morning,” Johnson said. “Then I got a call from the Chancellor’s office that he and the Provost were too busy and had to cancel. I almost had a heart attack. I told them he’s on his way, making a special trip just for this meeting. So, they agreed to drop by for 10 minutes and shake his hand.”

Christopher was able to ‘wow’ the Chancellor and Provost, though, who ended up meeting with him for more than an hour rather than 10 minutes.

“Tom was tremendous,” Johnson said. “He had every fact and figure. He got their ear and after that meeting they were both very interested in this energy initiative.”

The next step in getting the support needed to build the energy program was winning approval from the UNC General Administration. Again, it was industry representatives who carried the ball.

“It was all about workforce education at the time,” Johnson said. “I realized we had to have industry people delivering this message in Raleigh. I passed that ball to Dhiaa and he led the charge getting other people involved such as Boomgarden, Jeff Merrifield, Jim Little and others.”

The president of the UNC System, Erskine Bowles, was soon on board, as was North Carolina Governor Bev Purdue. At that point, the project had the money it needed for design and site work.

“Now we needed the money for construction,” Johnson said. “It was a bad time for the state economy in 2010. In those weeks leading up to final legislative decision on the budget, though, gas prices soared to $3.50 a gallon from $2.50. I’m convinced those soaring prices showed them how important energy was. I certainly believe that was a key bit of good luck.”

Persuaded by rising energy prices that a strong energy program was needed in North Carolina, the legislature allocated $76 million for the construction of the EPIC building. It also allocated $5 million a year in recurring money for 37 new energy-related faculty positions.

Construction was completed in the summer of 2012 and classes in the 200,000-square-foot EPIC building began that fall. Formal dedication was November 16, 2012.

The EPIC building became the new home of the Department of Electrical and Computer Engineering, the Department of Civil and Environmental Engineering and the collaborative EPIC research center. Housed under one roof, researchers, undergraduates and graduate students now had the opportunity to study and collaborate with each other and with leaders in the energy field.

Some of the outstanding laboratory features of the new building included a high-bay structural facility with a three-story strong wall, a Smart Grid lab with real-time digital-grid simulator, several power systems labs, and a large state-of-the-art environmental lab.

The U.S. Green Building Council awarded the EPIC building a Leadership in Energy and Environmental Design (LEED) Gold certification. Energy efficiency and environmental aspects of the building included a high-tech cooling system, a rain collection system, natural lighting from a central atrium, motion controlled lights, precise window locations and treatments that let in light but kept out heat, and other energy-reducing technologies.

The EPIC research center now had the space needed to develop and grow its collaborative, multidisciplinary programs with the purpose of uniting the academic and research expertise of the university with the great wealth of energy engineering talent in the Charlotte region. In coordination with the academic department, EPIC educational concentrations and programs at the undergraduate and graduate level emphasized the application of engineering skills on energy challenges. Collaborative research areas included power transmission and distribution systems; grid modernization; design, manufacturing and testing of large-energy components and infrastructure; renewable, nuclear and fossil generation technologies; and environmental impacts.

(For more information on the EPIC research center see ‘”The Centers” section and “EPIC” chapter.)

Department Name Changes

To better represent their academic focuses and new programs, several of the Lee College of Engineering’s departments added new words to their names in their later years. Electrical Engineering became Electrical and Computer Engineering in 1998, Civil Engineering became Civil and Environmental Engineering in 2007, and Engineering Technology became Engineering Technology and Construction Management in 2007.

Electrical Engineering had added a new Bachelor of Science in Computer Engineering program prior to its name change. The Computer Science Department had also left the college in 2000. “My first step when I became chair was to change the name of the department,” Farid Tranjan said. “We actually had the BS in degree Computer Engineering before the name change. We made the name change to better recognize the new program and to maintain the name ‘computer’ in college after computer science had gone.”

The name change for Civil Engineering brought the word “environmental” back to the department after a 26 year absence. When it was first created in 1973, the department was named Urban and Environmental Engineering. College leaders changed the name to Civil Engineering in 1981. Then in 2007, it became Civil and Environmental Engineering.

“We added ‘environmental’ to our name to show we had a strong environmental focus in our curriculum,” said David Young, who was department chair at the time. “We had kept curriculum updated and in line with what industry wanted, what was good for student careers and what our accreditors wanted. This included a growing emphasis on environmental engineering.”

The name change also better represented the research focus areas of department faculty members and graduate students. Working in conjunction with IDEAS, research areas included sustainable energy infrastructure, water and wastewater treatment, hazardous waste management, landfill evaluations, biomonitoring techniques and environmental health.

The Engineering Technology Department’s name and programs had been somewhat stable since their inception in 1973. That all changed at the dawn of the millennium, though, when the department began to add new undergraduate programs, freshman and sophomore study options, graduate programs and new words to its name.

A new undergraduate program ET added in 1999 was Fire Safety Engineering Technology. Like many of the Lee College of Engineering’s other new programs, Fire Safety began as a response to a community need. In this case, the profession of fire safety was becoming more technical and there was growing demand for fire professionals with bachelor’s degrees.

“The North Carolina Association of Fire Chiefs approached us about starting a program,” said Cheng Liu, chair of Engineering Technology at the time. “We met with Dean Snyder and Chancellor Woodward, and Woodward said we would need money to start program. The chiefs said ‘How much?” Woodward said, ‘$500,000.’ They said ‘okay’ and that they would get it. And they did. They went to the legislature and got the money.”

The ET department then hired the first faculty for the Fire Safety Engineering Technology program. Classes started in fall 1999 with 35 students. The program was the first of its kind in the southeastern United States. Designed to meet the need of the increasingly complex fire safety profession, classes and labs taught students about the engineering and technology elements involved in hazardous materials, chemicals, hydraulics, fire codes, fire management and other fire-related subjects.

Since their beginning, all of the Engineering Technology disciplines (civil, electrical, mechanical and fire safety) had been 2+2 programs. Students first completed two years of study at a community college where they earned an Associates of Applied Science degree, before enrolling in the UNC Charlotte ET program to complete their junior and senior years and earn the bachelor’s degree.

In 2004, the ET Department began offering a four-year option in addition to the 2+2 programs. By offering freshman and sophomore level courses, the department could meet the needs of students who were interested in engineering technology and in a traditional four-year college experience. The new lower division options quickly became very popular and overall ET enrollment increased from 339 in 2003, to 632 in 2006.

In 2007, ET began another new undergraduate program when it started the Bachelor of Science in Construction Management. Since this was the department’s first non-engineering technology program, ET made the decision to change its name to the Department of Engineering Technology and Construction Management.

ETCM designed the construction management program to meet regional and national demands for professionals with the engineering, business and management skills needed to build the next generation of America’s infrastructure.

“The catalyst for the CM program was a combination of factors,” said Dr. Tony Brizendine, chairman of the Engineering Technology and Construction Management Department. “Among these was a departmental emphasis on infrastructure, derived from the knowledge that much of our national infrastructure must be repaired or replaced in the coming decades. Also, Charlotte was home to many engineering, consulting and construction firms, which positioned UNC Charlotte to be a major player in the education of construction managers for the global construction business.”

A unique aspect of the four-year CM program was that the first two years of the curriculum was shared with the BS in Civil Engineering Technology (CIET) program. After the sophomore year, students decided whether to complete the BS in Construction Management or BS in Civil Engineering Technology, or in some cases, both.

In 2012, ETCM introduced its first graduate-level programs. To support UNC Charlotte’s research goals, ETCM faculty were doing more and more research and they needed graduate programs to provide them with student research assistants. The Master of Science in Fire Protection and Administration, and the Master of Science in Construction and Facilities Management were the first two ETCM graduate programs.

The new fire graduate program consisted of a common core of courses with concentration options in either fire administration or fire protection. Fire protection prepared students to use modern fire protection methodologies, techniques and tools for fire protection design. The administration concentration prepared students to effectively manage the administrative decision-making requirements within public and private fire safety fields.

Fire Protection and Administration courses included human behavior in fire, fire and building codes, industrial safety and facilities management, fire dynamics, fire failure analysis, human resource management in emergency services, fire failure analysis, structural fire safety, performance-based design, law and fire Safety, leadership/conflict management in public emergency services, and organization and management of public fire protection.

The Construction and Facilities Management master’s offered a range of advanced courses and theses topics in areas such as safety and risk management, operation of constructed facilities, building information modeling, advanced construction planning and management, building energy management, facilities management financial analysis, facility instrumentation and controls, and more.

In 2013, ETCM began planning its third master’s program, this one in Applied Energy and Electro-Mechanical Systems. The program was designed to combine advanced studies in energy and the intersection of electrical and mechanical engineering.

“Almost nothing was purely electrical or mechanical anymore,” said Program Director Maciej Noras. “So, this program taught the integration of the two disciplines and the application of these disciplines in the broadly understood energy field. Such a mix of skills was becoming more valuable to employers and this program educated versatile engineers who could fit in almost anywhere.”

The first students in the program came from diverse backgrounds in a number of energy-related technical disciplines. Educational qualifications for the students included electrical and mechanical engineering technology and engineering, physics and other related scientific and technical disciplines.

The AEES masters required students to take 15 credit-hours of common core courses, and then fulfill a remaining 15 credit-hours requirement through either a master’s research and thesis option, or a non-thesis coursework option.

“This new master’s program was very important to faculty,” Dr. Noras said, “because it provided us with upper-level students to help with our research. From the start we had a number of exciting research projects going such as magnetic gears, power generation from underwater currents, improving the efficiency of combustion engines, and energy harvesting from electromagnetic fields.”

AEES courses included energy generation and conversion, energy transmission and distribution, systems dynamics, applied mechatronics, energy management, analysis of renewable energy systems, fuel cell technology, and advanced instrumentation.

Systems Engineering and Engineering Management

In the case of what would eventually become The William States Lee College of Engineering’s fifth department, a graduate program actually came first and then, almost 10 years later, an undergraduate program. In 1999, the UNC General Administration approved the creation of a Master of Science in Engineering Management (MSEM) within the UNC Charlotte Lee College of Engineering. The program was the first step in the establishment of the Systems Engineering and Engineering Management program, which became an official UNC Charlotte department in 2014.

The interdisciplinary MSEM graduate program was a technical alternative to an MBA. It provided engineers and technical professionals with preparation for advanced careers by teaching them managerial competence in technological operations.

To accelerate research in engineering management, the Lee College of Engineering created the Center for Lean Logistics in 2005. The mission of the center was to become the premier logistics and engineered systems analysis portal in the region. The center quickly developed strong alliances with industry and government agencies to facilitate the pursuit of research projects and collaborations. It established a logistics and engineered systems analysis software lab, an industry benchmarking database and professional development programs. It also promoted the exchange of ideas on logistics and engineered system best practices and the latest technology and procedures.

To increase the accessibility of the MSEM program, the UNC System as part of the UNC Tomorrow initiative created an online option for the program in 2008. “The strategy was to reach working professionals throughout the state and beyond, who otherwise would not be able to continue to advance their education,” said program director Ertunga Ozelkan. “The primary delivery medium was asynchronous, which offered students more flexibility on when and where to view lectures and do their course work.”

The online delivery of the MSEM program was further enhanced in 2013 when it was expanded to include international students. Also increasing the accessibility of the program were new fast-track and combined classroom/distance options.

“The beauty of the MSEM program was its flexibility,” said Ozelkan. “You could take some classes on campus and some online, or you could take all classes on campus or all online. Students could go to school full time and finish in three semesters, or if they were working and raising a family and wanted to go at a slower pace they could take one class per semester and finish in about 27 months.”

With the master’s program in engineering management firmly established, college leadership began considering an undergraduate option that would help grow the college.

“We realized we needed an undergrad program that would be a feeder to the Engineering Management masters, and we needed a bigger college,” Johnson said. “We didn’t have many departments. Systems engineering was a very attractive option. I thought it was a very contemporary field. More and more engineering was including issues at the systems level such as systems integration and systems design.”

The college proposed and won approval of a new Bachelor of Science in Systems Engineering, and classes began in 2008.

“A changing global business environment was creating the need for professionals who could combine various operations including design, production, manufacturing, logistics, sales and service,” said Gary Teng, director of the new Systems Engineering program. “Systems Engineering provided this critical need of education to handle the increasing demands of systems efficiency, effectiveness, and integration in engineering and business operations.”

Systems engineering had very broad applications in a wide variety of industries including energy, telecommunications, construction, manufacturing, transportation and distribution, information technology, financial services, automotive, retail, healthcare and airlines. Its application pertained to all levels of an organization from entry level positions to top management.

“SE integrated all the disciplines and specialty groups into a team effort, forming a structured developmental process that proceeded from concept to production to operation,” Teng said. “SE considered both the business and the technical needs of customers’, with the goal of providing a quality product that offered customers maximum value.”

The Systems Engineering bachelor’s program earned its first ABET accreditation in 2012. UNC Charlotte recognized Systems Engineering and Engineering Management as an official university department in 2014.

Systems Engineering and Engineering Management was renamed Industrial and Systems Engineering in 2023.

INES

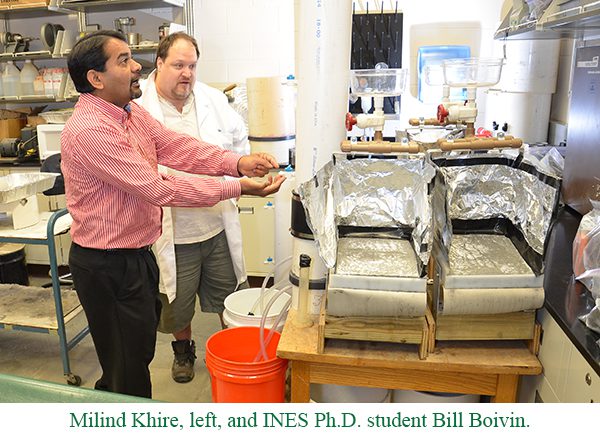

It was 2004 when Civil Engineering got the doctoral degree program it had been waiting for, in the form of the Infrastructure, Environment and Sustainability (INES) Ph.D. An interdisciplinary program that encompassed multiple UNC Charlotte departments, the INES program helped increase Civil Engineering research to a new level.

One of the planners and the initial director of the INES was David Young, who was also chair of the Civil and Environmental Engineering Department. “There was interest at the state level for interdisciplinary, multidisciplinary programs,” he said. “So, we put forth a program that engaged seven department and it got approved.”

The departments involved were Civil Engineering, Geography and Earth Science, Biology, Business, Systems Engineering, Chemistry and Architecture.

The INES program taught students to undertake complex challenges facing urbanized regions, specifically those issues related to the interplay between the environment and infrastructure needed to support economic and social development. Solutions to these challenges required an interdisciplinary approach that incorporated the engineering, science and management aspects of the problem. The program emphasized innovations in design, analysis, construction and operation of civil, energy and environmental infrastructure; and the scientific analysis of environmental systems. The program involved the development and sustainable use of renewable resources, and the protection of our earth and its environmental systems.

“The program hah some unique features, and provided the opportunity to work with faculty from other departments,” Young said. “I really enjoyed those aspects of it. Together we got the program up and running and it did very well.”

Young served as director of the program for nine years, before turning the helm over to Jy Wu of Civil Engineering. “Jy had been graduate director in Civil for 15 years,” Young said, “and said he’d like to lead INES. He came in and did a great job.”

Several new interdisciplinary research groups emerged as a result of the INES program. They included pavement materials, water quality, sustainability, infrastructure monitoring and atmospheric science. Other focus areas of INES research included climate change, civil infrastructure and materials, earth and geo-environmental systems, energy and environmental economics, environmental science and technology, integrated building design, natural hazards and geophysics, systems optimization and management, transportation systems analysis and operation and integrated watershed management.

“The INES program had 30 to 50 students a year on average,” Young said “It provided the opportunity for a number of faculty from multiple departments to bring in Ph.D. students, which gave them the opportunity to do more research. For that reason alone it was very successful.”

Freshman Programs and Student Support

The first engineering experiences of undergraduates in the Lee College of Engineering were the freshman courses Introduction to Engineering and Introduction to Engineering Technology, better known as ENGR 1201 and ETGR 1201, or more simply “1201.”

“This was a transition time for students when they were going from high school to college,” said Civil Engineering Professor Rajaram Janardhanam. “It was an opportunity to get students off to a good start and to get them motivated.”

In the 1990s, the college taught 1201 in two sections of about 200 students each. The course structure was purely lectures, which covered the different facets of engineering. A number of area engineering professionals visited as guest lecturers to tell students about their disciplines.

At one point, the university began to televise the 1201 courses live and students could take the class for credit by watching it on TV. “It was on every day at 5 p.m.,” said Civil Engineering Professor Johnny Graham, “running at the same time as Oprah and all these others other shows. The camera scared Dean Snyder more than anyone. I hated it too, but somebody told me to treat it just like another student and that’s what I did.”

The responsibility for the teaching of 1201 rotated among the faculty members.

“In those days,” Janardhanam said, “one faculty member spearheaded the program. The classes were huge. It was a lot of work and the students were not getting a very good experience. I wrote the proposal to make the classes smaller with more sections like they are now. Patty Tolley then took over the program and did an excellent job getting freshmen off to a good start.”

Tolley was a Lee College of Engineering alumna herself, having completed her bachelor’s and master’s degrees in mechanical engineering at UNC Charlotte. A non-traditional student with a husband and child, Tolley understood firsthand the many challenges of getting an engineering education.

Following her graduation, Tolley went to work for Duke Energy. In 1995, she also began teaching thermodynamics on a part-time basis at night for the college. “I found I loved it and loved the kids,” Tolley said. When the opportunity arose for her to work full-time in the college as a faculty associate for the mentoring program, she jumped at the chance.

She immediately had the opportunity to improve the freshman engineering program. “We used to put 200 kids in a large lecture hall and try to teach them teamwork and design, which was crazy,” Tolley said. “The teaching of the course rotated through the faculty, who would apprentice for one semester and then be the lead teacher for a year. The problem was no one wanted to make any improvements, because by the time they started teaching it they thought ‘I’m going to be out of here in a little while, so let the next person do it.’”

It was 2001 when the college decided to reduce the class sizes. It fell to Tolley and her new hire, Cathy Blat, to teach all of the new smaller sections. “We started paring down the size of the classes and were teaching about six sections each,” Tolley said. “But it really allowed us to get to know the students. We also started making the course a very hands-on, project-based experience.”

With financial support from Dean Johnson, Tolley was able to hire additional faculty dedicated to teaching 1201. Special new classrooms were also constructed in the Smith Building to be used exclusively for 1201.

In addition to the improvements to the freshman engineering program, Tolley created and expanded the college’s student support programs. She had named her department the Office of Student Development and Success when she started in 1999, and OSDS began offering a number of programs aimed at improving student retention and building an improved academic experience.

“Back then we had no budget, we had no space, we had nothing,” Tolley said. “I had a little bit of money to hire some students to be coaches, but really the students who worked with us were doing it because they were interested in helping other students. Whatever mentoring and instruction programs we came up with were developed by students for students. They took ownership, because they wanted other students to be successful. It was just so neat to watch it.”

The programs the students developed included mentoring, supplemental instruction, transition and tutoring. All of the programs relied on students who had previously completed a course with an “A” or a “B” to then share their knowledge and experience with the new classes of students. The programs became the basis of the Maximizing Academic and Professional Success (MAPS) program within OSDS.

In fall 2002, OSDS started the Freshman Learning Community (FLC), with 62 engineering and engineering technology students living together on a floor of Hawthorn Hall dormitory. The FLC encouraged freshmen to achieve success through a tight-knit community of persevering students, dedicated staff and involved faculty. In addition to living in a common area, FLC students attended classes together through block scheduling, and attended workshops, supplemental instruction and examination review sessions held in their dorm.

The FLC was extremely successful, with a greater percentage of its students being retained in the college between their freshman and sophomore years. The program grew in popularity and eventually the freshman engineers took over the entire Hawthorn Hall dorm.

In 2003, OSDS started the Lee College of Engineering Leadership Academy, a two-year, extra-curricular program modeled after leadership training programs for young professionals in industry. The Leadership Academy prepared undergraduates to successfully fulfill leadership roles on campus and in the engineering industry by building their leadership abilities. With sponsorship from AREVA, the program included off-campus retreat weekends, a field trip to AREVA and a capstone service project completed directly by the students. College faculty, industry executives and academy alumni facilitated the program to provide real-world perspectives on issues relevant to the engineering industry.

Other achievements of OSDS included taking on the task of centralized advising for freshmen, and providing students with professional development opportunities such as mock interviews, job shadowing, instruction for the Fundamentals of Engineering Exam, and job fairs through events such as the college fall picnic.

“Our motto was that anyone who was admitted to the college could succeed,” Tolley said. “We then set about providing the academic support programs to make this possible.”

Senior Design

As the culmination of four years of hands-on engineering education, senior design projects were part of the Lee College of Engineering for decades. The scope, financial support and organization of the capstone projects progressed through a number of evolutions in the academic departments and the overall college, ultimately creating one of the largest and best capstone experiences in the country.

Early senior design projects in the 1970s were directed by departmental faculty. Most were one-semester projects that involved individual students and sometimes small teams of two or three.

In the late 1980, when Norm Shul began working for the College of Engineering to build the co-op and internship programs, he also recruited a few senior design projects from industrial partners. There was no formal program or effort to build such an external program, though, and most of the projects originated from jobs that students were working on for their industry employers.

The first concentrated effort to build programs that would pair students with industry partners on real-world engineering senior design projects began about 1990, when the college hired Jack Roblin as its industrial liaison.

“Jack Roblin was recruited by Snyder,” Tranjan said. “He, along with Bob Coleman started the concept of senior projects with outside funding. The program was called the Creative Projects Laboratory. Projects were funded with $5,000 from the outside sponsors, who then got seniors to work on a project for them. The program had maybe 15 or 20 projects before it kind of faded out when Roblin retired. Most people think our senior design program started about 2005 with the program we have now, but it’s been around for a long time.”

Senior design projects continued in a number of different forms, most of them based on the academic requirements of the individual departments. Mechanical Engineering created and sponsored many of its own projects, especially in the area of motorsports, where student teams worked together on race car projects. Civil and Environmental Engineering also set up one-semester projects within the department that brought together the different elements of their program such as environmental, geotechnical, structures and transportation engineering. Examples of the civil projects included land development assignments for things like light rail, airports, and commercial and industrial land use.

A concerted effort to create a senior design program that was built on industry-sponsored projects began in the Mechanical Engineering Department. ME Chair Jay Raja hired Frank Skinner to develop the program, and the concept quickly caught on across the rest of the college. Johnson expanded the program to a college level that crossed department lines.

“Jay Raja got the concept going in ME,” Johnson said, “and then it grew to become a college-wide program. When I was a department chair I was frustrated with senior projects. Our kids could never build anything, because we had no money. They got 50 bucks to spend. With the new industry sponsored projects they got $5,000.”

The college organized the centralized senior design program within the new Industrial Solutions Laboratory and hired Bill Heybruck to run the organization. An alumnus of UNC Charlotte’s Electrical Engineering Ph.D. program, Heybruck came from Hitachi as the new director of the Industrial Solutions Lab.

“There were only six or seven sponsored projects in the fall of 2007 when I started,” Heybruck said. “By 2012, we were up to 20 sponsored projects out of a total of 87 projects. In all there were about 240 to 245 students involved.”

Heybruck and his college committee of departmental representatives established the structure and deliverables for the program. Projects began with discussions between industry sponsors and the committee to develop a scope of the work. Projects descriptions were then posted online the first week of classes for seniors to review. Each senior then applied for the top three projects they wanted to work on. The committee made the project assignments. Students and their sponsors then met for the first time at a kickoff breakfast the second Friday of the semester.

As the senior design program evolved, the committee added several mid-point design and prototype reviews to the course requirements. The reviews ensured teams were making the necessary progress to be on schedule for a mid-year poster presentation of their design solution, and then the year-end completion of the project.

“We set up more deliverables,” Heybruck said, “which really improved the quality of the designs and the final projects.”

Working in a real-world environment of deadlines and deliverables taught the seniors a number of skills including planning, budgeting, teamwork, presentation and public speaking.

“The soft skills were important for engineers to learn,” Heybruck said. “We required all the students to speak at team presentations, which took a lot of them out of their comfort zone. But the presentations got better and better.”

The two-semester senior design projects began in both the fall and spring semesters. For the first semester, the teams developed their designs. In the second semester they completed the construction and final work. The culmination of the projects were the spring and fall Senior Design Expos, where judges selected the top projects.

Some of the notable projects over the years included the design of a stand to support the Miracle on the Hudson aircraft at the Charlotte Aviation Museum, a nuclear plant manway cover removal system for Shaw Group, a transformer monitoring systems for Schweitzer Engineering Labs, a Combat Heat Stress Prevention Kit for the U.S. Air Force Research Laboratory, and a water-driven electrical generator for Chitokoloki Mission Hospital in Zambia.

Some of the companies who consistently supported the program and sponsored projects over the years included AREVA, NASA, Shaw Group, Irwin Tools, Duke Energy, Siemens, EPRI, Westinghouse and URS.

“One of our biggest successes was the senior design program,” Johnson said. “It was a tremendous addition. It allowed our students to do some incredible projects, because they actually had the money to build them. We were way out in front even nationally, and now we’re seeing the popularity of similar programs at engineering schools all around the country.”

The Students

The William State Lee College of Engineering’s first priority was always the education of its students. Some thoughts about these students from a few of faculty members who dedicated their lives to teaching them follow:

Yogi Kakad – “I always noticed a common thread among our undergraduates in that a lot were first-generation college students who had a good work ethic, were very polite and had a lot of drive. For them to get the chance to go to college involved a lot of sacrifice from them and their families. They felt privileged to get to go to college and they worked hard. I felt myself privileged to be able to work with such students. It was a privilege to teach them.”

Patty Tolley – “Our student body contradicted a lot what is in the engineering education literature. If other institutions found common themes about what makes students successful and what engineering students are traditionally like, a lot of times our student body did not reflect that.

“We had a large population of first-generation college students and they were students who really appreciated the hands-on learning we provided here. That’s the thing that set us apart. We were not just about the theory and concepts. The students actually got their hands dirty working in the labs, and our students liked that experience. The students were the best part of my job. I just loved the students.”

Bob Snyder – “In the early days of the college, most high school students from the Charlotte area who thought they wanted to be engineers usually went to N.C. State. If they ran out of money, got home sick, had a girlfriend back home or whatever, then they came back home to Charlotte and to UNC Charlotte. We had a lot of transfer students back then, and they were some of our best students. It wasn’t until the 90s that we got many freshmen applying here.”

Marty Kane – “By the time they became seniors, there was usually a nucleus of students who were all in the same classes together. And every year had a different personality to it. Some classes were great and it was usually because of strong leaders. And with others classes you would think, ‘boy do they need a rudder.’”

Norm Schul – “In our co-ops, many of the students were doing the programs because they needed the money. The engineering students were easy to sell. They were very focused, knew what they wanted and were well equipped to handle responsibility in their companies. They represented us well. When I made a site visits, almost all of them were excited to show me what they were working on. They were enthusiastic and the employers couldn’t say enough good things about them.”

John Daniels – “We had a unique culture of applied, hands-on learning here. Employers often said our graduates had the same technical prowess as students from other institutions, but on average our grads were more business savvy, more professional, and had more discipline and character. Part of the reason for this was our demographic of a number of non-traditional and first-generation students. We had a lot veterans and students of an older age range, and together, they brought a lot of life experiences to the classroom that rubbed off on the traditional students. It helped infuse a culture of practical, above-average common sense and understanding of why things work the way they do, which was part of our mission and focus.”

David Young – “The students in the 2010s were moving to a more traditional, full-time, live-on-campus group, and I think that was a good thing. There was a slight change in the nature of our class make ups. We had younger students who were just out of high school, and still fresh in their minds was the math, physics and chemistry they had learned. So in teaching them, I could give a little more attention and spend more time on how the application of engineering tied back to the chemistry and physics. In the past, I tied the application of the engineering to the real-world experiences the students had. I actually enjoyed trying to come up with a bridge that helped students understand the material, and those bridges were different for the older students and those fresh out of high school.”

Bob Johnson – “I found when I came here that there was a culture in the South of middle-class families with strong work ethics, and that’s where most of our students came from. They wanted to learn and were good student to teach.”

Rajaram Janardhanam – “Students were my life. Working with my students and teaching the classes, that was my bread and butter. In the early days, I knew each and every student by name. I really enjoyed working with the students. Even now I have good relationship with many of my former students. Students were the whole reason we were here.”

Bob Johnson

Johnson came to UNC Charlotte in 1994 from the University of Illinois at Urbana-Champaign where he had been a mechanical engineering professor and department chair. His educational background included a Ph.D. and M.S. in Engineering Science from the California Institute of Technology, and a B.S. in Mechanical Engineering from SUNY at Buffalo, New York. His research specialization was in fluid mechanics. He came to UNC Charlotte as chair of the Mechanical Engineering Department, and in 2000 became dean of The William States Lee College of Engineering. Some comments about Johnson from his colleagues follow:

Jerre Hill – “When Bob Johnson came on board it was a good thing. The first time I saw him and here was this young guy coming down the hall who could have been a grad student, I thought “My God, I hope that’s not our new department chair.” But it turned out to a good thing.”

Working with Johnson in building the motorsports programs was very rewarding, Hill said. “We kept getting students who worked for race teams, and finally it occurred to us that we should start a program for these guys. It all happened because of Bob Johnson’s courage and vision. I was just kind of in the right place at the right time. Bob gets all the credit.”

Ian Ferguson – “Bob Johnson was quiet and understated, but had great vision. You have to look at what happened around him. We moved into Woodward, Duke, EPIC and motorsports. The growth under his leadership was tremendous. When you brought people to the campus they were amazed.

“I’ve liked his style as Dean. He stayed out of the way and let people get on and do their thing.”

Penny Bovender – “When Johnson first came in as chair he looked like the stereotype rumpled professor. He was loud and unlike anyone else in the college. In every sentence he spoke he told you how they did it at Illinois. We eventually got him trained, though, and he turned out to be a good guy.”

David Young – “As Dean, Johnson was running a college that was spread out over five buildings. He had the responsibility of growing and nurturing a lot of programs, with thousands of students and multiple facilities. Through a period of remarkable change and growth, he stayed focused on the mission of student-focused programs and application-based research and academics.”

Patty Tolley – “Bob Johnson was a fearless visionary who made huge changes in the college. He was always looking five to 10 years down the road and got people excited about the vision he had. He was the father of the motorsports program and EPIC. He was always very supportive of OSDS over the years, even in the lean times.”

Conclusion

For its first 50 years, The William States Lee College of Engineering remained dedicated to applied, hands-on education that prepared all of its students for successful careers in all aspects of engineering and technology. The college created new programs, constructed new buildings, and developed research programs, all with the mission of adding value to engineering and technology education. While serving the needs of and partnering with the regional engineering community, the college provided opportunities for students to learn and work with professional companies. The commitment to students was steadfast, and the impact of this focus resulted in successful programs for undergraduate and graduate students, and also researchers and community partners.

“We were a very special institution,” said Jay Raja. “We had a special mission in training students who had the capabilities to succeed, and it was up to us to help them reach their potential and become full-fledged graduates. It was very rewarding.

“The other thing that was satisfying for me was building the new buildings. We built a really terrific infrastructure. I would say we had the best engineering buildings of any college I knew of. Others may have had more square footage than us, but we were able to move into new space designed specifically for engineering study and research.”

Many of the Lee College of Engineering’s accomplishments were tied to its relationships with the Charlotte community and the state of North Carolina.

“Much of our success was being in the right place at the right time,” said David Young. “An example of this is the success of EPIC. The state of North Carolina and Charlotte were very progressive in developing this region as an energy hub and developing energy as the new economy for the state. This all aligned perfectly for EPIC to emerge and the college of engineering capitalized on it.”

As a growing university, UNC Charlotte provided young faculty with opportunities to really learn how universities worked as they built their careers.

“The opportunities I had here to see multiple aspects of the university, I know for sure many of my colleagues were not been able to see at their institutions,” Robin Coger said. “Because of the growth going on here, and the rate at which that growth was happening in my time, I was able to be involved in and see a little closer many aspects of the university. I think that was a wonderful thing to get to see.

“One of the other things I always think was wonderful about UNC Charlotte was we had some really great people here. Whether it was administrative, staff, faculty or students, I think we had people who really cared about the university. When you have that, you have an experience I wouldn’t trade.”

John Daniels agreed with the wonderful opportunities UNC Charlotte and the Lee College of Engineering provided.

“It has been a great experience,” Daniels said. “I remember talking with Vincent Ogunro back in 2002 about our decisions to come here. We both agreed it was going to be a good place for a faculty member to grow and succeed, and that was 100 percent correct. It was a great place to grow along with the institution.”

The relationship with the community was also a great strength of the college, Daniels said. “We were very fortunate to be in Charlotte. We had very generous engineering firms here; generous in terms of input into designing our curriculum and participating in our lectures. There were always practicing professional engineers in our hallways who were engaged with the program in one way or another, and it was our students who benefitted.”

The impact on and benefits to students was always the primary consideration in all Lee College of Engineering programs and projects.

“Our theme has always been the students come first,” Johnson said. “Our main mission was education and preparing the next generation of engineers. Sometimes a research agenda can interfere with that if you don’t keep a clear eye on the target. Engineering schools become great through great undergraduate programs that graduate well-trained, well-prepared engineers. That is what we tried to do.”

The credit for the Lee College of Engineering’s successes belonged to the hard-working faculty, Johnson said. “The faculty did the really heavy lifting. It was a team effort. Everyone committed their life’s work to the college.”

In its first 50 years, the achievements of The William States Lee College of Engineering were many. “I think we did a hell of a lot,” Johnson said. “We went from a modest organization to a pretty serious organization. When I look around now I say, ‘Wow, look at what we’ve accomplished.’ And I can say that in the past 20 years I’ve had a major role in making it happen. We’ve graduated thousands of engineers who are now contributing to the community and are leading rewarding, productive lives. It makes me proud. We have accomplished our mission.”